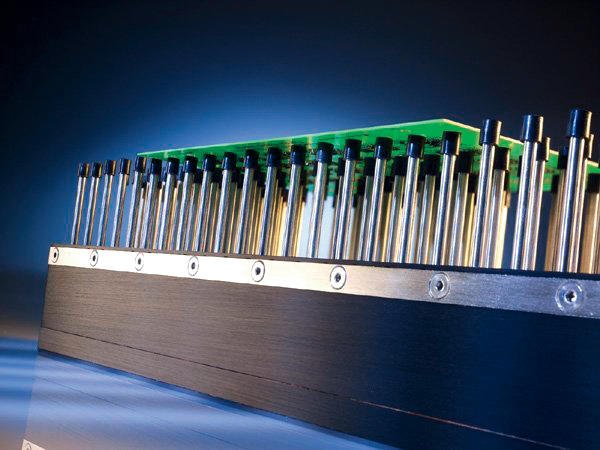

DEK has unveiled the latest addition to its range of advanced tooling technologies. Building on the proven strengths of the automated Grid-Lok tooling system, HD Grid-Lok is a high density tooling solution designed to support the entire PCB assembly and drive enhanced productivity without the need for manual intervention. Its 12 mm pin pitch can be set-up in seconds to provide complete and flexible board support. Activated at the touch of a button, this tooling fixture completely eliminates set-up overheads, requiring minimal intervention from the line operator and eradicating the delay associated with dedicated tooling fixture configuration.

The flexibility of this automatic tooling system is ideal for high changeover manufacturing environments, delivering effortless integration at the product changeover stage to eliminate the potential for human error. Based on a modular foundation concept, HD Grid-Lok will conform to any given board profile to deliver cost-effective manufacturing on demand. For all subsequent boards, the system can be re-set in seconds to meet diverse assembly requirements. The system easily conforms to individual substrate topographies, with pins automatically locked into position to emulate a custom-tooling plate on even the most densely populated boards. As DEK Platform Manager Steve Watkin explains, “HD Grid-Lok delivers excellent print accuracy and paste volume repeatability to meet a range of manufacturing challenges.”

Productronica, Stand A4.305

EPP Europe 439

Share: