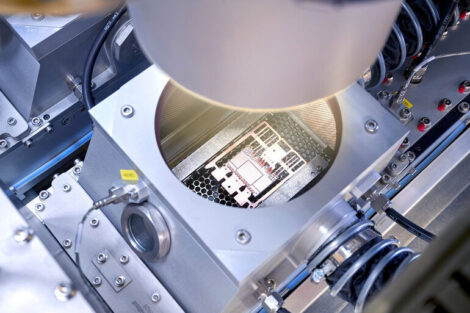

The equipment series Auto-Vision-Expert has been developed to provide the most effective rework station. Placement accuracy depends completely on the calibration of the optical path. In addition, there is the uncontrolled ‘blind’ descent after manually aligning the component. The Expert 09.5 eliminates this risk. The manufacturer uses the fixed camera lens of the Auto-Vision-Placer. From beginning to end of the automatic placement process it is controlled and calculated by it. From precise acquisition, continuous supervision to controlled lowering, only a few seconds pass while the user follows the steps on the screen. The software Easy Solder-05 offers more clarity and better optical assistance for each step and correspondingly easier use. Just three mouse clicks takes one to the process. The PC then sets the process data (times, temperatures, air flows etc.) and the DBL controller ensures exact adherence to the parameters. The PC automatically records an illustrated protocol.

The new Rapid-IR underheater transfers the basic heat energy into the PCB without exceeding the permitted maximum heating rate of 3.5 °C/sec. This basic heat reduces the thermal stresses in the board..

The advantages of the Auto-Vision-Expert 09.5 are also shown by the versatility of possible applications. PCBs from just a few millimetres to 500 (in the XL version to 600) mm can be accommodated and in just a few seconds the workstation is adjusted to suit any SMD type and size.

EPP EUROPE 418

Share: