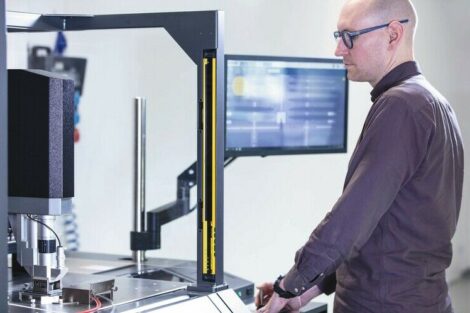

The Polaris Jr. is a standard flexible assembly cell that can easily be redeployed on the factory floor or even economically retooled for other synchronous or lean final-assembly applications. The flexible assembly cell allows the integration of single-process functions such as final-assembly dispensing, screwdriving, and now pick-and-place. More than 20 functional modules plug into a standardized tool interface that uses a common architecture and common controls and comes into cell sizes from 500 mm to 2.5 meters. The benefit of scalability is obtained by providing solutions tailored to customer needs. The assembly cells concept translates into “off the shelf” prices and lead times, offering total flexibility compared to customized machines. The company’s technology position is supported by a strong research base in process development and materials research, such as reliability testing and defect analysis and design optimization. The firm develops documented process solutions for OEMs and CEMs, PCB layout and design, topic expert failure analysis, prototyping and design for manufacturability. It offers feeding systems such as the Polaris assembly cell and transport systems.The firm performs die bonding/flip chip and advanced SM as well as mechanical assembly and dispensing.

SMT, hall 7, 512/Nepcon UK, G52

EPP Europe 450

Share: