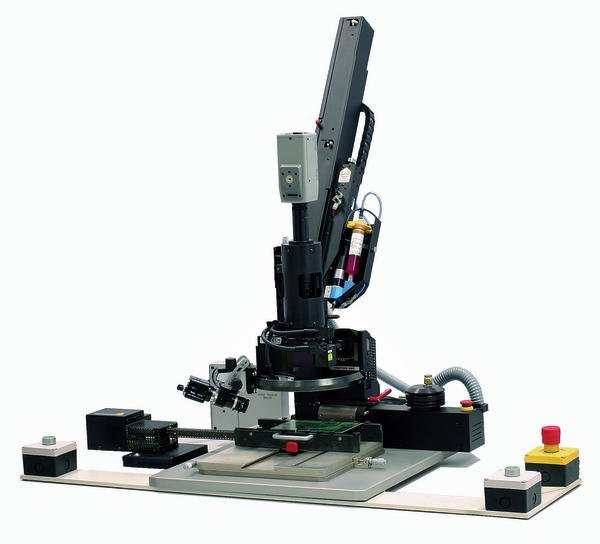

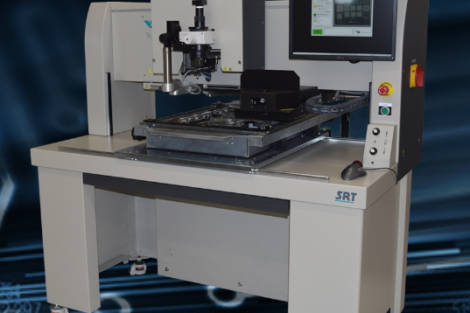

In a world of ever smaller components, the application package “Micro Rework” is committed to rework applications, for example, single ball repair, µCSP or small passives like 01005. Typical rework cases are misplaced or deformed balls, wrong-sized balls, ball bridges or blank positions on a SMD component. Manual repair by hand must be ruled out because ball size and pitch are getting even smaller. The system can handle ball sizes smaller than 200 microns. The application package “Micro Rework” from Finetech for the Fineplacer Pico includes the following modules: Local area hot gas bottom heater, hot gas reflow module Comiss IV Plus, motorized swivel module, high magnification optic, Inspections video system Vario Plus as well as application optimized soldering tools.

The tooling for single ball repair is especially suited for solder removal, ball handling (pick & place) and soldering of a new ball. There is no other tool necessary to accomplish all rework processes. With a standard soldering profile, the complete process time for all steps (solder removal, ball pick & place, fluxing, soldering) may take less than three minutes. With motorization the system achieves a degree of reproducibility unrivalled in manual rework and minimizes operator influence. The system is capable to perform in a large field of rework applications from smallest devices up to standard BGA’s. The application package is an option to enhance the performance of the system, older systems can be retrofitted with this package. The company offers also a “Micro Rework” application package for the automated systems with optical ball inspection system to detect failure types and location.

EPP Europe 419

Share: