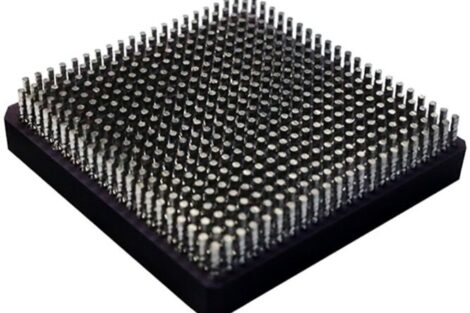

SJ7 solder alloy from Almit Technology Ltd. is characterized by its significant mechanical advantages over conventional tin-lead solders. SJ7’s resultant ability to deliver a superior performance under highly challenging conditions is currently driving its widespread adoption in aerospace and military applications.

“Those in the military and aerospace industries require complete product reliability and consistency – without compromise. This is why SJ7 has been developed, optimized to deliver an exceptional performance in high demand applications, involving harsh environments, thermal cycling and high strain,” explains Chris Ward.

Extensive testing has confirmed the paste’s ability to offer manufacturers dramatically improved tensile and creep strength properties over traditional tin-lead solders at both room and elevated temperatures. In addition, SJ7 also exhibited impressive wetting capabilities and exceptional yield for significantly higher throughput. Meanwhile, a highly refined grain structure also means that during thermal cycling, Mean Time Before Failure is greatly increased for manufacturers using SJ7.

Available in both solder paste and wire form, SJ7 displays excellent printing, slump and reflow properties. The high strength solder paste is supplied with a Rosin Mildly Activated (RMA) Flux and, notably, does not require manufacturers to alter existing tin-lead profiles.

EPP EUROPE 425

Share: