In this interview, Mark Challingsworth, the Global Head of Marketing at Heraeus Electronics, discusses how fast the industry is changing and the increasing demands that calls for this growing pace. He explains what companies should focus on in order to succeed with today’s trends and what is yet to come. He also further discusses the developments and what the future of the company will look like.

What is the company’s USP and how does it differentiate from other competitors?

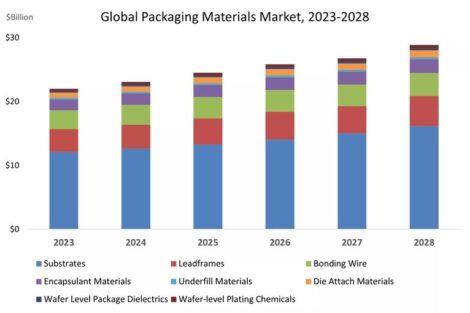

As we have talked to and worked with customers in the power electronics, semiconductor and LED industries, there is a growing trend toward the streamlining of their supply chains. There is an increasing demand for partners who can deliver simplicity and expertise from a complete portfolio perspective of packaging materials, and that certainly plays to our strengths. We are an expert for materials and matched materials solutions for electronic packaging. Our product portfolio ranges from substrate materials with metal substrates, and metal ceramic substrates to thick film materials, solder products and sinter materials, as well as, adhesives and both heavy and fine bonding wires.

We also strongly invest in R&D facilities. Customers profit from our application competencies and engineering services in our application centers and prototyping facilities around the world. Next to our Customer Applications Labs in Germany, Singapore, and Shanghai, we have recently opened a SMT Customer Applications Lab in Philadelphia, to work collaboratively with customers in the Americas, to resolve specific performance challenges, manage joint development projects and support the design and simulation of processes. We can bring a broader, integrated, and holistic approach to our customers’ needs.

The solder paste product series that was released at productronica, how has this benefited clients?

We developed the new solder paste to help manufacturers address the competitive cost challenges of the market while delivering superior performance. We had a lot of great feedback from the show last year. The F498 soldering paste is a lead-free, low-temperature solder paste, specifically designed for step-soldering when a second, lower temperature reflow process is needed, which is often used in consumer electronics and telecommunications. The soldering temperatures are lowered by 70 °C to 80 °C, so it also reduces the energy consumption of furnaces.

How has the speed of the changing industry affected clients?

The electronics markets are dynamic and evolve at a very fast pace. A short time-to-market for new products becomes a crucial sales advantage. Two other trends that will continue to grow in scope are price competition, obviously, and the rising expectations on device features. Only those who optimize design and processes will succeed. Regardless of the customer’s specific needs, every product or solution we offer is guided by three essential principles: help our customers to shorten development cycles, bring down costs, and reduce risks in all the applications they are working on. If you can help your clients in those three areas, it can help them keep them competitive and innovative in a fast-changing market.

What are some other challenges that the company has seen recently?

There are many challenges companies are facing today. The functionality of devices keeps increasing and it needs to fit into a smaller footprint. With less space, it becomes crucial to develop materials that can perform with smaller form factors and increase performance and functionality. At the same time, more electronic functions in smaller spaces result in higher power density, so that the heat caused by power losses needs to be dissipated. Therefore, thermal management also represents a major challenge. Our application centers around the world help to build prototypes and see how future devices can be structured in order to achieve optimal performance.

What are future trends that can be seen in the semiconductor industry?

More than Moore will drive the semiconductor industry in the coming years. Focus has shifted from transistor scaling to advancements in device system packaging with smaller form factor components. The application of assembly materials is critical to guarantee high yields. We are therefore developing advanced packaging products with our ultra-fine Welco powder to give customers the ability to attach their components with very fine features, up to Type 8 solder powder.

What other innovations will be released this year?

We recognize the continuous need for innovation to enable customers in achieving their goals. We support the drive for miniaturization while maintaining high yields and providing effective cost solutions to our customers. In power electronics, we have a new sinter paste for high power density packages, as well as, a high reliability solder paste for Die Attach and DCB. But we’re also creating innovations for the LED industry with our multi-layer substrate for LED Chip on Board (CoB) applications, as well as our non-pressure pin transfer silver sinter paste for high power LEDs requiring high thermal dissipation and precise positioning.

What does the future for the company look like?

It looks very bright for us. We will continue to focus on growth markets including power electronics, automotive and advanced packaging. As society and industry becomes more energy efficient, power electronics will play a key role. While devices become smaller, the need for advanced packages will grow. Our products and solutions are being used in all these devices. We also see strong growth opportunities in the battery sector with our wires and roll-clad products for cell-to-cell connections and our thick film pastes for heaters. We are continuing to develop from a materials supplier to a solution provider, offering our customers perfectly matched solutions for their innovations. And with a global network of research labs located close to customers, research and development is a 24/7 operation. It enables us to quickly move our customer’s challenges from the research lab to the real world, so they can compete and succeed.

SMT Hybrid Packaging, Booth 4–554