Solderstar was founded by Mark Stansfield and Patrick McWiggin in July 2002, Mark a Software Engineer and Patrick an Electronics Design Engineer. The company’s first product offering was a 4 channel profiler aimed at the reflow soldering market, primarily with a target market of small/medium size companies new to profiling due to the change to lead free. EPP Europe interviewed the Managing Director and founder Mark Stansfield to get more information about the company, their products and the soldering process.

SolderStar provides products for the entire range of soldering equipment – does this make you unique?

I believe so; as you can tell from the name SolderStar, it is 100% soldering which is our business and we have the complete range of solutions for reflow, wave solder, and more recently selective solder and vapour phase. We are continually improving and developing the products and working with our customers to provide the solutions that they require. So yes, I believe we are unique and our products cover whatever the engineers are using in the manufacturing lines. We always have a solution and will work with individual companies on special projects to meet their specific needs.

As a supplier to the equipment manufacturing industry, how do you see the market?

It’s been a tough few years, and I am not sure that we are coming out of the recession yet, but certainly our sales are increasing, perhaps this is due to our development work.

What do you think is the most sort after product at the moment?

Selective soldering is becoming an interesting process. For many manufacturers we have had a system in place for over one year, but the main development work we have been doing in 2013 is with the flux monitoring side of that process. Currently there is no electronic method to record and measure what goes on in terms of fluxing circuit boards before the soldering process takes place, so we have been listening to our customers’ needs and have products, which I believe arte a first, which allows the engineer to measure these extra parameters within the new process. I think our success is down to the development of our systems and moving forward with the design and technology of our products having listened to our customers’ requirements.

In your opinion, what will be the products in the main stream in the coming years for information technology? What will be their assembly characteristics and your solutions to them?

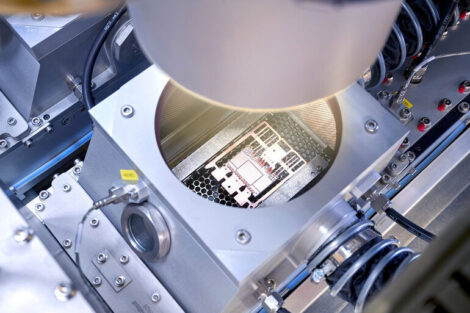

Consumer electronic goods are following the trend of increased functionality while physical constraints remain fixed, or in the case of emerging sectors like wearable ‘gadgets’, new manufacturing methods and material are needed for ultra-miniature high technology assemblies. Our solutions are well placed to help with developing the thermal processes for these challenging areas. Our latest reflow optimisation engine, Autoseeker 2 can search through millions of reflow oven setpoint possibilities in a matter of seconds to find the best possible process settings for these sensitive assemblies. Combined with the SolderStar APS (Automatic Profiling System), these provides a powerful combination of optimal profile setup and 100% monitoring of every assembly through the production line.

What products are of most significance to you this year and what are their advantages for the downstream manufacturers?

Our latest SolderStar PRO Reflow profilers – industries smallest datalogger, yet still providing direct USB and Wireless telemetry. We have produced systems for customer profiling assemblies down to 60mm in width, when tunnel heights are minimal this product comes out top with the lowest Heatshield height available due to its ultra slim-line footprint. WaveShuttle PRO – our leading wave solder analyser. Unsurpassed measurement performance for conventional wave solder machines. Dedicated wave measurement circuitry and production robustness makes it possible to measure wave contact time, temperature and crucially wave height in a single pass, multiple times every single day.

Reliability is one of the major concerns in manufacturing, how do you help to improve it?

I like to believe that every feature we design into our products is done for a purpose, and productivity is a big influence on those decisions. Profiling tools are definitely 50% a software product; we have continually evolved the software supplied with our instrument, our early customer were smaller manufacturers who were new to profiling, and not always having dedicated engineers to manage the thermal process. We pioneered the approach of presenting solder process result in graphical form rather than in the traditional tables of data, realising that understanding the process condition was much simpler and hence quicker this way. Our tools also make the job of periodic checking the lines a much less onerous task, we have robust fixtures to allow rapid checking of a thermal process without the need for troublesome test boards, plus integrated SPC tools to quickly draw process information from the historical data.

How about enhancing assembly process efficiency?

The tools help in a multitude of ways, we operate a common platform across all 4 soldering processes which reduces training time and centralisation of profile data. Our software is extremely easy to use, it provides all the powerful tools an engineer expects to see but we also have put real effort into making both the hardware and software easy to operate for all levels of user. Secondly, as manufacturers evaluate changes in more flexible or cost effective soldering technologies, they place demands on instrument manufacturers to help them by providing any new solutions they need to smooth this transition. One example of this is the Multi-Wave product, this new instrument concept provides an engineer necessary measurement system, sensors and software to quickly build his own test fixtures to evaluate each and every tooling design he currently uses.

Defects in SMT process is another big concern. Downstream manufacturers will inspect and identify the defects to avoid the inferior products being shipped into the market, or find ways to prevent defects from happening. Obviously the latter seems to be more significant, how does your company help the manufacturers?

I am a great believer in ‘You Can’t Manage What You Don’t Measure’, profiling spans all levels of manufacture and we are have a product range to cover the needs of each. To produce electronic assemblies without a known profile is just asking for trouble further down the line, either rework costs or early failures and unhappy customers. Not every company warrants investment in equipment to continuously monitor the production lines, but to not profile an assembly during the NPI stage and then performing some form of periodic checking is to be frank just not doing the job correctly. The soldering process is a dynamic thing, with many outside influences affecting the profile seen at product level, machine loading , flux build up , extraction performance change or machine failure. All these things can be measured and controlled with the adoption of a quality control procedure. As a minimum, verify the machine before a new batch is sent through the line is common sense, for long running production batches periodic checking would also be prudent. For customer who need complete traceability, then we can help with that also, the APS (Automatic Profiling System ) system tracks the profile of every assembly that passes through the oven, where PCB barcoding is available we are working with customer to interface to internal ERP systems automatically store and sort profiles by type, batch and Work ID.

How can the SolderStar thermal profiling technology promote energy saving and environmental protection in the whole electronic manufacturing?

Our profiling tools have been a key piece of equipment where energy savings need to be made. Process throughput does not always need to be the defining production criteria in many cases. Where slower throughputs rates are feasible, it is possible to have a process which is well within specification utilising lower heater set points and hence using less energy and reducing running costs. The AutoSeeker system makes this whole procedure very simple, we capture the existing performance of the current process , then using a profile simulation engine can scan through the millions of possibilities to find the settings required for the oven to run with lower energy consumption.

With electronic manufacturers turning to intelligent devices such as wearable devices, what are the challenges brought to the thermal profiling in the soldering process?

Ultra-miniature electronic assemblies will prove a real profiling challenge, traditional sensor attachment methods using exposed junction thermocouples, tape, high temperature solders may prove problematic. Fine gauge sensors will need to be used, we currently produce down to a size of 40AWG TC sensor wire which achieves a very small side sensing junction. This would originally developed for use with profiling under BGA’s. These sensors give good results and response times, but are an order of magnitude more fragile. Products like the SolderStar APS – Automatic Profiling System, which measure the performance of the process for every assembly will need to be employed, reducing the need for test profiles to be performed with very fragile assemblies and give a high degree of confidence that the soldering process is tightly controlled.

SMT Hybrid Packaging Booth 9-323

Share: