Solderstar was founded by Mark Stansfield and Patrick McWiggin in July 2002, Mark a Software Engineer and Patrick an Electronics Design Engineer. The company’s first product offering was a 4 channel profiler aimed at the reflow soldering market, primarily with a target market of small/medium size companies new to profiling due to the change to lead free. EPP Europe interviewed the Managing Director and founder Mark Stansfield to get more information about the company as well as their targets.

Tell us a little bit more about SolderStar and where it all began?

We quickly gained distribution partners around the world and continued to expand the product range as our exposure to the market increased. We currently have distributors in all major markets and over 2500 instruments helping engineers around the world with their soldering processes.

Why is it so important for thermal processes to be controlled? And why is thermal profiling the key to successful lead-free manufacture?

The solder process is the key ingredient that firmly comes under the control of the manufacturer, when lead-free emerged as an established process many manufacturers had major upheaval of their well proven thermal processes. The problems of new components, PCB and solder pastes required for this new process were solved by strategic partners, but the new settings for the production process were specific to the manufacturers machines in use, assembly complexities and chemistries of the newly selected solders. This is where our early sales slogan, ‘Thermal Profiling – your key to lead free’ came from. The available processing window is much tighter with leadfree, making the one profile fits all much less likely. Our profiling tools are now extremely advanced, we can take a snapshot of what the thermal process is doing today and using software simulation tools produce the optimal settings for the engineer in a matter of minutes. Without correct settings on the machines, solder quality is impaired and components could be damaged. Our tools also help processes to be established which utilise less energy.

I understand you are the only company that offers thermal profiling for all 4 soldering methods, that is reflow, vapour phase, selective and wave, why are your products so versatile?

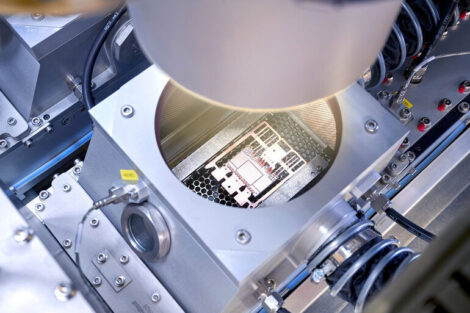

The SolderStar PRO systems have one key difference to other offerings; we do not rely solely upon thermocouple sensors to measure process information. Our datalogger is equipped with 16 thermocouple channels as temperature is core to all soldering processes, also memory , batteries etc., however additionally we have a communication system known as ‘Smartlink’ to allow intelligent accessories to be developed to measure process specific parameters. For example our WaveShuttle product is an intelligent pallet specifically developed for wave soldering analysis; it has its own measurement system on board to interface to 24 titanium contact sensors to measure all the wave parameters with accuracy x10 of any thermocouple based system. Using this system approach results in higher performance in terms of measurement accuracy and repeatability, but more importantly provides a single datalogger solution which is flexible and can be expanded to every process as required.

What makes SolderStar ‘stand out from the crowd’?

Support, flexibility and focussed products. We have a dedicated and knowledgeable team, who working with our distributors can react quickly and competitively to customer’s needs, from bespoke hardware systems to new software features. We are an engineering lead company, and proud of both our range of products and levels of support we achieve. Our software is extremely focussed to the electronic industry’s needs, and we believe takes the next step from simple process setup to easing the task of fully documenting the process.

In your opinion why is it so important to use temperature profiling systems?

I am a great believer in ‘you can’t manage what you don’t measure’, profiling spans all levels of manufacture and we have a product range to cover the needs of each. To produce electronic assemblies without a known profile is just asking for trouble further down the line, either rework costs or early failures and unhappy customers. Not every company warrants investment in equipment to continuously monitor the production lines, but to not profile an assembly during the NPI stage and then performing some form of periodic checking is, to be frank, just not doing the job correctly.

Since the emergence of lead free soldering, your products have obviously become more popular, but what industries do you work with and where are you focusing your efforts?

SolderStar as you can guess from the name is 100% focussed on solutions for Electronics Manufacturers. Thermal processes exist in many industries and have similar problems that engineers need to solve, as with electronics manufacturing these solutions require specialist knowledge. Our decision was to diversify into these other industries by a strategic partnership with another UK company, Phoenix Ltd. Phoenix also act as distribution partner for SolderStar in Germany providing local sales, service and calibration for the complete range of products.

What countries do you sell your products into and where is your strongest market?

All major manufacturing markets around the globe. Of course we are strong in our home UK market, but our company could not survive without export all around the world. In our early days our initial business grew quickly in China, our strategy was to partner with the distributors of the western oven machine brands which worked well for us selling many systems along with new machine sales. China has changed greatly as a market, given our strength in engineering and local presence, our main growth markets are now UK, Germany, France and Italy. Our products have been well received with some of our more recent developments tailored to further our growth in targeted markets.

Many operators simply take temperature profile measurements as their benchmark for process control – why is this not enough?

A soldering process is a dynamic thing, with many outside influences affecting the profile seen at product level, machine loading, flux build up, extraction performance change or machine failure. All these things can be measured and controlled with the adoption of a quality control procedure. As a minimum, verify the machine before a new batch is sent through the line is common sense, for long running production batches periodic checking would also be prudent. For customers who need complete traceability, then we can help with that also; the SolderStar APS (Automatic Profiling System) system tracks the profile of every assembly that passes through the oven. Where PCB barcoding is available, we are working with customers to interface to internal ERP systems which automatically store and sort profiles by type, batch and work ID.

Can you talk us through your top three products and their USP?

SolderStar PRO Reflow profilers – industries smallest datalogger, yet still providing direct USB and wireless telemetry. We have produced systems for customer profiling assemblies down to 60mm in width, when tunnel heights are minimal this product comes out top with the lowest Heatshield height available due to its ultra slim-line footprint. Combined with our AUTOSeeker software tool, this system optimises where other profiler cannot go. WaveShuttle PRO – our leading wave solder analyser. Unsurpassed measurement performance for conventional wave solder machines. Dedicated wave measurement circuitry and production robustness makes it possible to measure wave contact time, temperature and crucially wave height in a single pass, multiple times every single day. The SolderStar VP Pro – Vapour Phase is a very common process in our customer base, and it is usual to see wave or selective soldering also in operation at the factories. SolderStar’s VP solution utilises our miniature datalogger common to all processes. VP is a harsh process and we provide the high thermal protection required through a low mass Teflon coated thermal shield fitted with a high level of lightweight thermal insulation. Where our system really wins is when vacuum stages are present in the machines, our wireless telemetry system uses ‘mesh networking’ techniques to maintain the real-time data feed to the engineer throughout all stages of the process.

What products are you currently working on developing?

Flux measurement systems for selective processes. The position and amount of flux deposited before the soldering process takes place is still un-controlled by electronic methods. The methods required are quite different from the measurement systems we currently use. We have a working system that allows the presence of flux to be detected via a newly developed sensor + measurement electronics. We are currently building a test platform to allow further development in conjunction with some of the major machine manufacturers in the market.

What are the productivity benefits from using SolderStar equipment?

I like to believe that every feature we design into our products is done for a purpose, and productivity is a big influence on those decisions. Profiling tools are definitely 50% a software product; we have continually evolved the software supplied with our instruments. Our early customers were smaller manufacturers who were new to profiling, and not always having dedicated engineers to manage the thermal process. We pioneered the approach of presenting solder process result in graphical form rather than in the traditional tables of data, realising that understanding the process condition was much simpler and hence quicker this way. Our tools also make the job of periodically checking the lines a much less onerous task, we have robust fixtures to allow rapid checking of a thermal process without the need for troublesome test boards, plus integrated SPC tools to quickly draw process information from the historical data.

You are going to be exhibiting at Productronica, what can we expect from SolderStar at the show?

It will be our 6th visit as exhibitors to this key show, we will have a complete range of products available for demonstration. I am not a great believer in ‘we must have something new for the show’, continuous improvement and listening to you customers is more important, but undoubtedly our new developments are driven by this key date in the exhibition calendar. Our main design work in 2013 has been around the detection of fluxing in terms of position and amount on machines with selective fluxing capabilities. Currently mechanical methods are used which do not lend themselves for periodic checking or SPC gathering activities, we are working on a range of sensors and instrumentation upgrades to allow our customer to capture this information and produce quality control documentation in the same way as all other parameters we measure from the soldering process.

Productronica, booth A4.145/3

Share: