Zero defect manufacturer in Malaysia

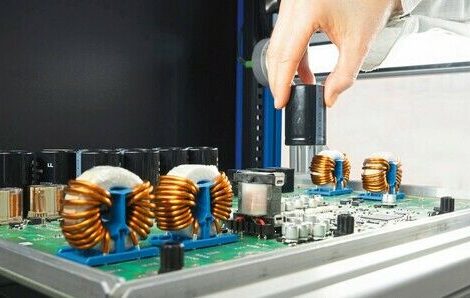

As our Cover Story, the manufacturer of high-end medical equipment, Paramit Corporation, has recently opened an environment-friendly facility. Relying on Ersa‘s high performance selective soldering technologies, the company is constantly improving their process to have a very close to zero-defect production. They recently acquired 5 systems, not only because of the familiarity with them, but also because of the first class customer support.

Green factory in the forest

Expectations for this year‘s productronica

2017 is just around the corner. Over 1,200 companies are expected to be presenting a wide range of products and services, as well as, their latest developments and innovations. With the Highlight Days, roundtable sessions, interactive live shows, parallel fairs, and competitions, topics like automation, IoT, Smart Factory, Industry 4.0 will definitely be addressed.

Come visit us at our Booth 281 in Hall A2.

LED protection in tough environments

The LED industry has been continuously growing, not only because of its efficiency, but also because of its durability and adaptability. However, there are many factors that need to be considered in order to enhance the longevity, as well as, the performance of an LED. Depending on environment changes, exposure to a variety of elements or chemicals, and its utilisation, different protection media will be needed.

Correct selection of protection compounds

Best inspection coverage

Although AOI and SPI technologies have been around for a long time, it is only recently that there‘s been a development and an improvement to these systems. Companies are now offering the use of 2D and 3D technologies in one machine, which provides a comprehensive overall test coverage, while reducing errors and false calls. Some components may not be found and inspected by a 2D inspection, but with 3D, and vice versa. When making an investment with inspections systems, specific parameters should be considered.

When production experts benchmark 3D AOI