One major growth motor in the electronics industry is the increasing digital networks in both the industrial and private sectors, including the automotive industry and e-mobility. However, in the production of electronic assemblies, equipment manufacturers and EMS providers are faced with enormous cost pressure. “Zero-defect strategies” are a major component when it comes to taking up these challenges.

In terms of meeting the demand for zero-defect production, smart sensor technology plays a major role and is being increasingly incorporated into soldering machines and systems. In a soldering process, printed circuit boards are connected with electronic components of every kind. The methods range from simple hand soldering to mass soldering processes such as reflow, selective or wave soldering. In order to achieve stable quality, and meet the associated demand for zero-defects, permanent monitoring of the assembly’s specific side conditions and the process parameters of the soldering systems is indispensable. The primary requirements in terms of printed circuit boards and components, such as wettability, soldering heat requirement, soldering heat resistance, layout, etc. have to be assumed as constants and presupposed in a soldering process. These preconditions cannot be adequately controlled in a soldering system but are essential for the quality of the soldering process.

Arising from this fact, the soldering system process inspection can only monitor some of the parameters, which contribute essentially to the quality of the electronic assembly. The aim of a “zero-defect strategy” in soldering is therefore to eliminate those soldering system factors, which can directly influence the process, from the outset.

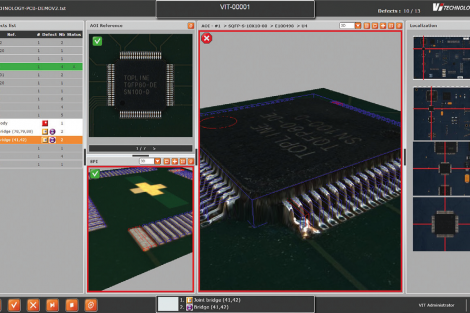

Beginning with the solder paste printing, the position and volume of the solder paste depot are inspected. Where deviations are detected, the results are immediately used in the system to make process corrections for the immediately following assemblies.

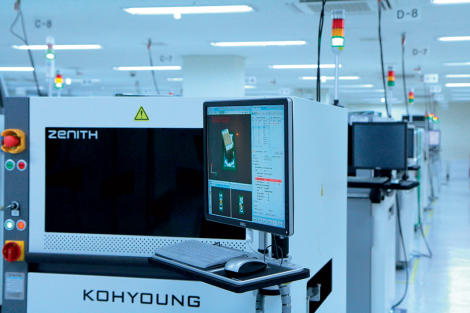

Thermal processes are monitored by determining the degrees of heating in known masses. In this way, the energy transfer is monitored, and stability ensured in the heating of the assemblies. Wave and selective soldering involve further factors as well. The flux application is a very closely monitored process, as the soldering result is directly related to the quantity of flux applied. Further parameters relating to the solder wave are the core of the soldering process. In modern soldering machines, the latest image processing systems are used here. Among other things, they serve to monitor the process and settings and measure the height of the solder wave.

A further important component in the context of the “zero-defect strategy” is constituted by standardised processes on which modern production facilities increasingly rely. In the selective soldering area, the selective soldering system always consists of the same components, such as flux module, pre-heat module and solder module, regardless of the configuration level and the system type. This allows products to be switched from one line to another, under the same process conditions.

When the diversity of influences is considered, it quickly becomes evident that, in real production, the zero-defect target is extremely difficult to achieve. For this reason, it makes much greater sense to develop and introduce strategies with which the “zero-defect” target can be asymptotically approximated. In this context, the monitoring of the soldering process is a very important, individual stage of production. Altogether, however, all the quality-relevant details in an electronic assembly must be taken into consideration. As all these factors are subject to constant change, a “zero-defect strategy” is a process which needs to be continually lived out and enhanced. We now end with a frequently-cited quotation from Confucius, which goes… The way is the goal…

About the presentation

The presentation shows the efforts being made today to safeguard soldering processes. But even with the most perfect monitoring of individual functions, we must still always be clear about the fact that, in the soldering process, a multitude of quality-determining electronic assembly features come together, all decisive for the result.

Statement

The development of Europe’s industrial landscape depends primarily on the competitive capability of the companies. Whether operating locally or globally – today’s world market framework conditions make forward-thinking orientation, and a high level of innovative power, indispensable. Only with constant innovations will it be possible to ensure the success of the companies in the medium and long term.

As a medium-sized engineering company with a tradition going back for decades, we place our technological lead and our innovative power at the service of our customers, allowing them to sustainably optimise their production processes in terms of quality, costs and delivery. With the zero-defect strategy, each company takes a different approach; here Ersa is making the decisive contribution. We look forward to interesting discussions and a lively exchange of information, and wish the participants productive contact with experts that will successfully advance their future-securing projects. We have the solutions for the challenges you face when it comes to soldering!

Listen to the presentation live at

Budapest, May 25th, 9am – 5pm

Budapest, May 25th, 9am – 5pm

Register for FREE

Please use the registration code OLHUN17