In order to avoid the defects in production someone must know, very precisely, the individual process steps and their tolerances.<!-more–> Only the very clear distinction between the production requirements and inspections’ tolerances of the process deviation helps to achieve the goal of zero defect production. The minimum deviations are from an optimized process. The more accurate and certified measurement data must be base of it.

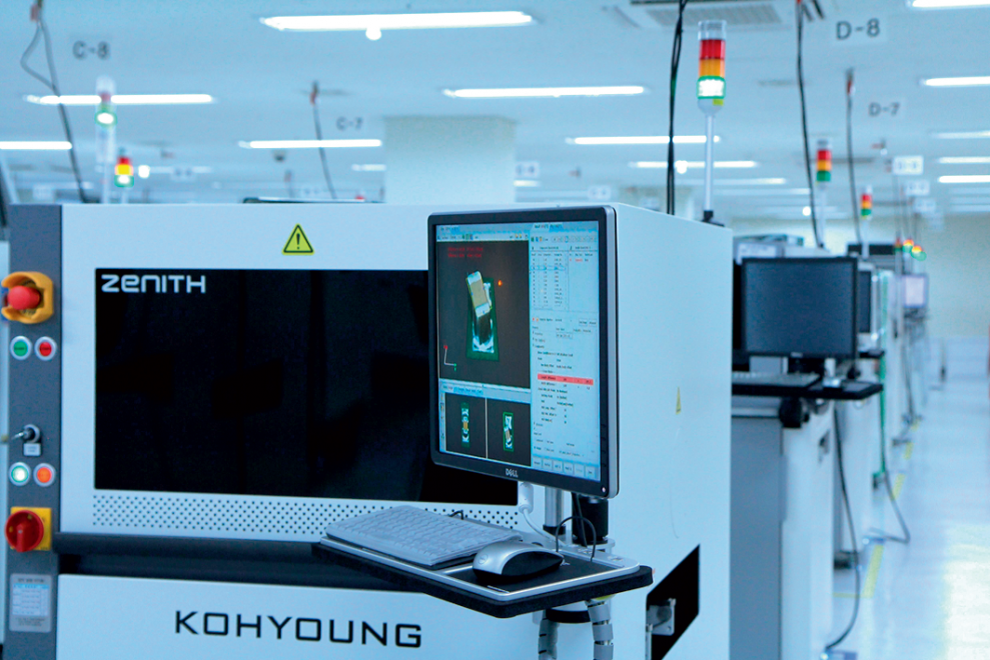

Electronics manufacturing in Europe is increasingly demanding and each board has its own challenges. In order to obtain the quality and reliable product, the key is a solid automatic inspection. Koh Young’s product portfolio includes 3D SPI systems, pre-and post-reflow 3D AOI systems.

With the installed 9.800 systems worldwide, the company is successful. Since 2005, after 12 years still the market and technology leader in the field of 3D measurement technology – the international company provides know-how and innovative solutions. Thus, Koh Young systems also meet the highest requirement of electronics manufacturing.

3D solder paste measurement

A 3D solder paste inspection system is virtually irreplaceable in today’s assembly of products. Ensure that only well-printed circuit boards are transferred to the next process step. Koh Young’s patented SPI measurement technology provides the highest measurement accuracy, reliability and speed. Over 2.000 customers worldwide confirm the outstanding technology. From the real-time process visualized feedback on the individual process steps, including their control, the company provides its customers an optimum system.

The 3D solder paste inspection system is also used for analyzing weak points in the printing process as well as optimizing the entire production. With the real 3D measuring solutions, reliable systems are developed and offered for comprehensive monitoring and optimization of the manufacturing process.

Unique 3D AOI Technology

With the innovative 3D measurement technology, the 3D-AOIZenith offers an incomparable flaw. Pseudo-errors, slippage and personal programming results are definitely a thing of the past. Through the use of 100% 3D measurement in combination with classical 2D inspection technology, the Zenith is able to handle the challenges through component shading, warping of the printed circuit board and various construction suppliers. A parametric programming, which can of course also be carried out completely offline, makes the test result independent of the programmer. The setting of test parameters and threshold values does not require any special experience in image processing. The system is based on a component library for the rapid creation of the test program, since already set parameters and threshold values for components without adaptation can be taken over completely uncomplicated. The system measures all component attributes, from position to solder joint, polarity, etc. in 3D. By measuring the height for each individual pixel, there is no dependence on light or shadow, so that fine-tuning is superfluous.

To the lecture

Zero defect is the goal of any modern, profitable manufacturing facility. If in the past, the errors were determined and analyzed and thus the cause was turned off, the prevention of errors is at the forefront today.

The precise recording of process influences is no longer sufficient. Smaller and smaller designs, which eventually force the designers to go to the design borders. The question is what is still reliably producible? Focusing on a perfectly optimized set-up of machines and materials as well as processes does not lead to the desired success.

The diverse requirements on the production and their employees, which are then to produce the smallest batches of 50, 100 or 1,000 pieces with the same quality or production efficiency, are also disturbing influencing factors. The well-known fish-bone chart cannot be the number of individual factors today (processes, machine, materials).

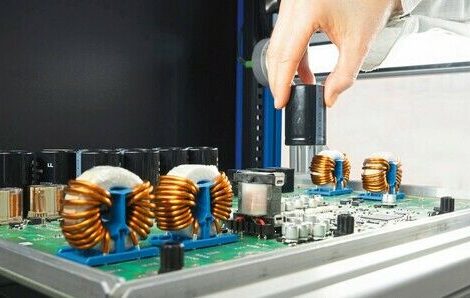

The precise monitoring of the individual significant process steps, such as paste printing, assembly and soldering process, allow a preventive reaction to avoid the actual error before the formation. The miniaturization mentioned above practically excludes the operator from recognizing these subtle differences in time. The exact measurement and recording of the individual paste deposits (area, volume, shape) as well as the placement accuracy, (twisting, offset coplanarity before the soldering process, but also the final result, the parameters of the individual soldering point (volume, solder rise, solder angle). In order to keep the production quality high and to maintain this high level even in small numbers. Only through this holistic detection can also conclusions about the delivery quality of components (housing tolerances, solderability, etc) with IC and fine pitch constant pin length as well as pin heights. Not least, the process stability of the solder paste used as well as the documentation of the circuit board quality are visualized.

Because often it is still possible to compensate for a deviation in the process, but the unfortunate combination leads then surprisingly increase of the failure rates. To avoid this, the employees at the line as well as the process managers have to get the tools for high-precision visualization at hand. Making decisions in real time helps to realize zero defect production.

Listen to the presentation live at

Budapest, May 25th, 9am – 5pm

Budapest, May 25th, 9am – 5pm

Register for FREE

Please use the registration code OLHUN17.