Zero Defect Production presupposes integrated holistic digital processing of production data. Strategies with respect to the Industry 4.0 concept so far focus on data transfer and standardization of interfaces. This alone, however does not allow for timely avoidance of production defects. How can this huge amount of digitized information of the processes be used in order to achieve an improved and more efficient production? In the following, this presentation will provide some solutions on how to act and react and/or timely interlock processes, if necessary.

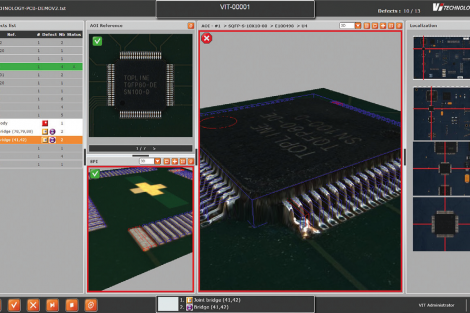

The entire NPI process should already be mainly based on digital information. This includes product design data, revisions, machine programs, work instructions and process data. The shop floor is provided with such data and the production process is planned together with all the necessary steps regarding production, test, calibration, adjustments and rework. In theory, this should enable a zero defect production. In practice however, there is a variety of disturbance variables that need to be recognized, measured and reacted upon accordingly. To digitally gather such information in a timely manner is a prerequisite for zero defect production. However, another challenge is to timely analyze and qualify such information. On the one hand there will be numerous digital measurements that lead to the required quality within a defined process window. On the other hand, there will be measurements that only allow for insecure statements regarding process stability and product quality. This includes numerous defect symptoms that can only be analyzed and hereinafter qualified by applying further examination and testing. Hence, qualified employees are necessary in most electronic productions who implement such assessments and analysis.

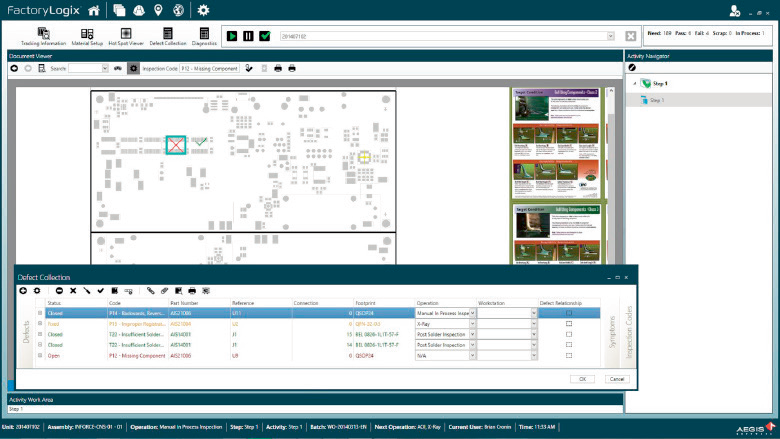

In the digital production world, this “manual” quality process should be included in the same way as any other automated production and test facilities. Again, the goal of zero defect production requests employees to have access to all information in order to analyze defects correctly, detect symptoms and understanding their correlation by constant learning. For this purpose, Aegis fully provides the production employees in electronic production with the original construction data in the current version as a digital template. With such prerequisite, we enable the employees to react on disturbance variables accordingly and to initiate process improvements. The zero defect principle should be embedded in the digital production process in order to make these measures effective in real time and in current production. This means that quality data analysis following the production does not contribute to zero defect production but only embedding such quality data surveillance in the current production process ensures the zero defect rate.

Disturbance variables have to be reacted upon in the current production in real time and such reaction measures have to be monitored again. Zero defect production means to produce without any defects in the first place and does not mean to select those products without any defects at the end of production. This requests that reaction upon defects and disturbance variables have to be included as a work step in the current production process. The integrated system, however is the prerequisite for an zero defect production because production and quality plans only allow for zero defect production in an integrated system and not independent from each other.

Intelligent Process Interlocking

Another great advantage of digital support regarding the production process and quality data surveillance is the feature to react upon disturbance variables with automated regulation mechanisms. Influences on disturbance variables can be reacted upon and or regulated with mathematical methods in case of a physical defined reaction of control loops. Statistical methods are applied in everyday practice of electronic production. Consequent implementation thereof during current production as well as quality data surveillance is a core element of the new Aegis solution.

At the beginning of the production phase, a process plan pursuant to the respective quality routes is designed for each product. The process parameters with the process windows are also defined and determinated in the planning. The process and quality manager does not have to design or develop everything from scratch but can refer to proven templates and individually adjust them, if necessary. As a result, an electronic „route“ is designed for production which is again used to monitor the compliance with the defined routes and quality data.

It would be possible to work with such a production and quality plan successfully if everything always worked smoothly in production. In practice, however, any interferences are opposed to this theory and it is mandatory to react upon them in a dynamic way. Mainly automatic algorithms that re-adjust the process based on feedbacks from the shop floor are very useful for this purpose. Any symptoms and defects that are determined in the current

production lead to an automatic reaction. The result of such reaction is documented and the monitoring of the implemented measure is integrated in the process flow in case of quality

improvement.

Any implemented measures have to be monitored continually in order to achieve the goal of zero defect production. This requirement is only practicable with a continuous digital solution for all process steps involved. In case planned measures, production or test steps have not been implemented, the system should react upon that automatically. Process interlocking is a crucial factor in the Aegis solution. This ensures that there are no scrap productions or uncontrolled process steps in the production. Correct reaction on incorrect conditions is herewith ensured permanently in the current production Operation

Statement

Working with digital product data on the shop floor is a prerequisite for zero defect production. Measuring and monitoring the manufacturing and process steps continually allows for timely recognition of any deviations. By using learning digital systems that draw the correct conclusions from occurring symptoms, will drive us towards zero defect production. Only a closed control loop provides a solution for a reaction on any interferences and the regulation in the production process.

About the speech

Topic of this speech is digital support covering the entire production process of an electronic product including the integration of the test and calibration steps until final shipment of the product. Zero defect production can only be realized under certain circumstances. This include dynamic reaction on newly occurring disturbance variables as well as monitoring of the adherence to each and any process parameters that are crucial for the product quality. A self-learning system that links symptoms and reasons for defects helps analyzing such defects and leads the way to avoiding scrap and missing parts production.

Listen to the presentation live at

Budapest, May 25th, 9am – 5pm

Budapest, May 25th, 9am – 5pm

Register for FREE

Please use the registration code OLHUN17