Low-standoff components, such as QFNs, are proliferating in electronics due to their increased functionality as well as lower cost. Power QFNs with high heat fluxes specifically need good thermal dissipation. Excess solder voiding, especially with the large lake voids beneath the QFN thermal pad (Figure 1a/1b) will affect thermal management and may reduce operational life of the PCB assembly.

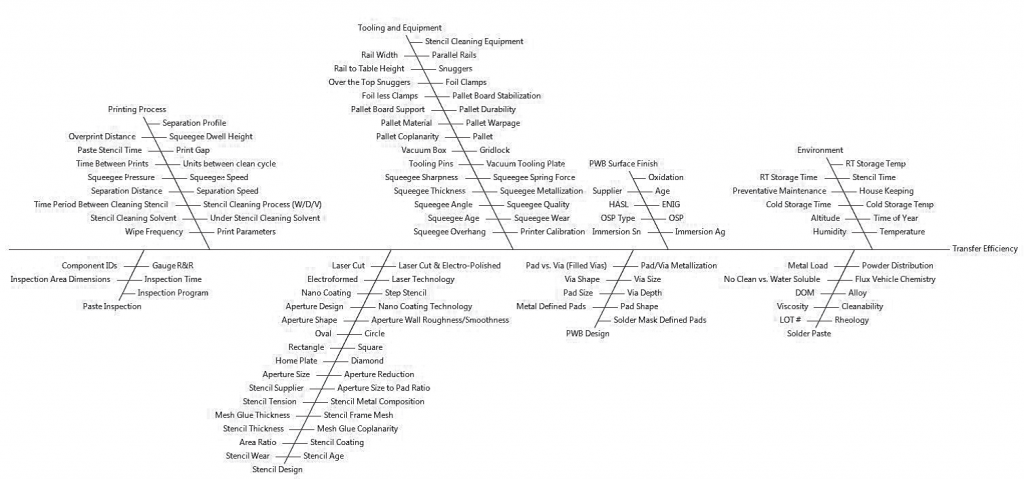

Figure 2 lists the variables that can influence voiding. Since there is no industry specification on QFN voiding, this study specifically looked at achieving less than 10% voids on the QFN thermal pad by looking at the effect of the variables of (i) reflow profile; (ii) stencil thickness; (iii) flux chemistry type. Voiding less than 10% was achieved in most instances.

Figure 3 shows the QFN ground plane of 7.75mm per side, and a windowpane stencil design of 2.2mm per side. The squeegee printing speed was set at 100mm/s to simulate high-speed printing for volume manufacturing.

Effect of the Reflow Profile & Flux Chemistry on Voiding

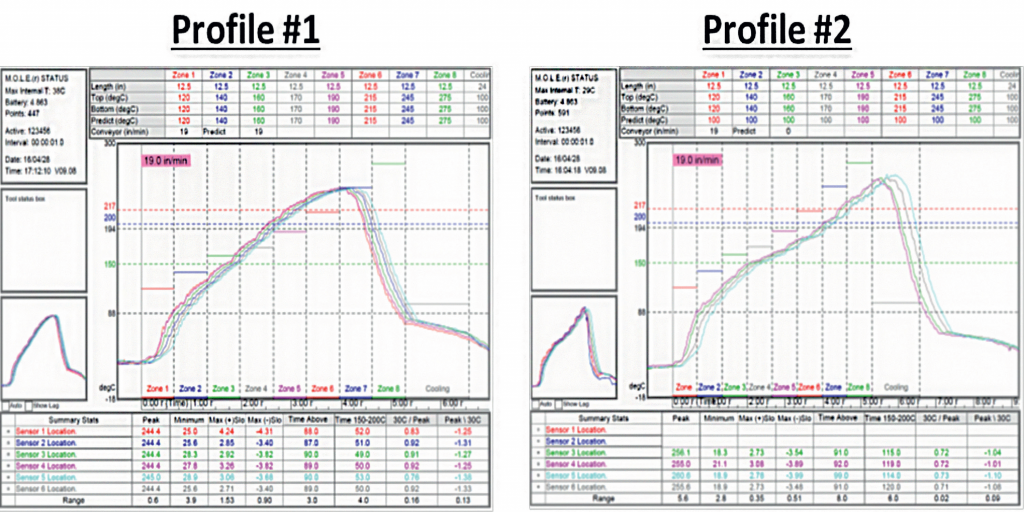

Figure 4 shows the two reflow profiles. Profile #1 is a ramp-to-peak profile with a peak temperature of 240°C ± 4°C, and time above liquidus of 70 seconds. Profile #2 has a slight soak and a higher peak of 254°C ± 4°C with time above liquidus of 77 seconds.

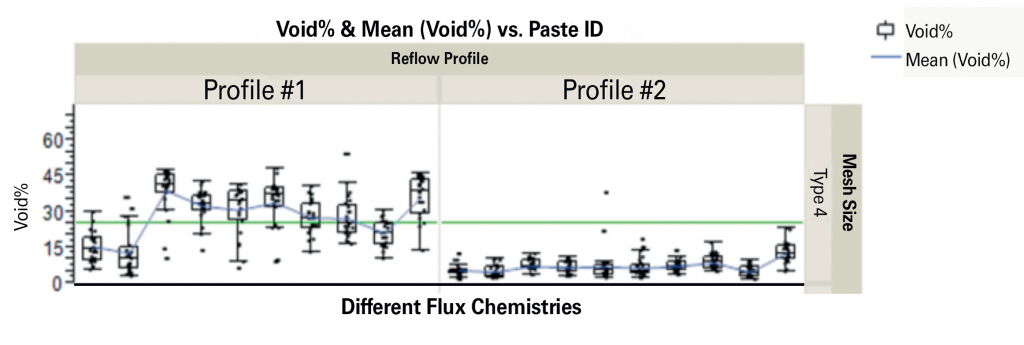

Profile #2 gave significantly lower voiding (10% in many cases) compared to Profile #1. Not only does Profile #2 significantly reduce voiding, the scatter in the data is also greatly reduced, as seen in Figure 5.

Our theory is that the hotter profile is more successful in driving out the volatiles than the cooler profiles. This concept is easy to understand when one considers that the vapor pressure of most solvents increases considerably at higher temperatures. But higher peak temperatures would cause more oxidation, therefore causing higher voiding. This paradox can be resolved only by utilizing flux chemistries with an enhanced oxidation barrier, which can effectively prevent/minimize oxide and still utilize the positive effect of vapor pressure with the higher temperatures.

Effect of Stencil Thickness on Voiding

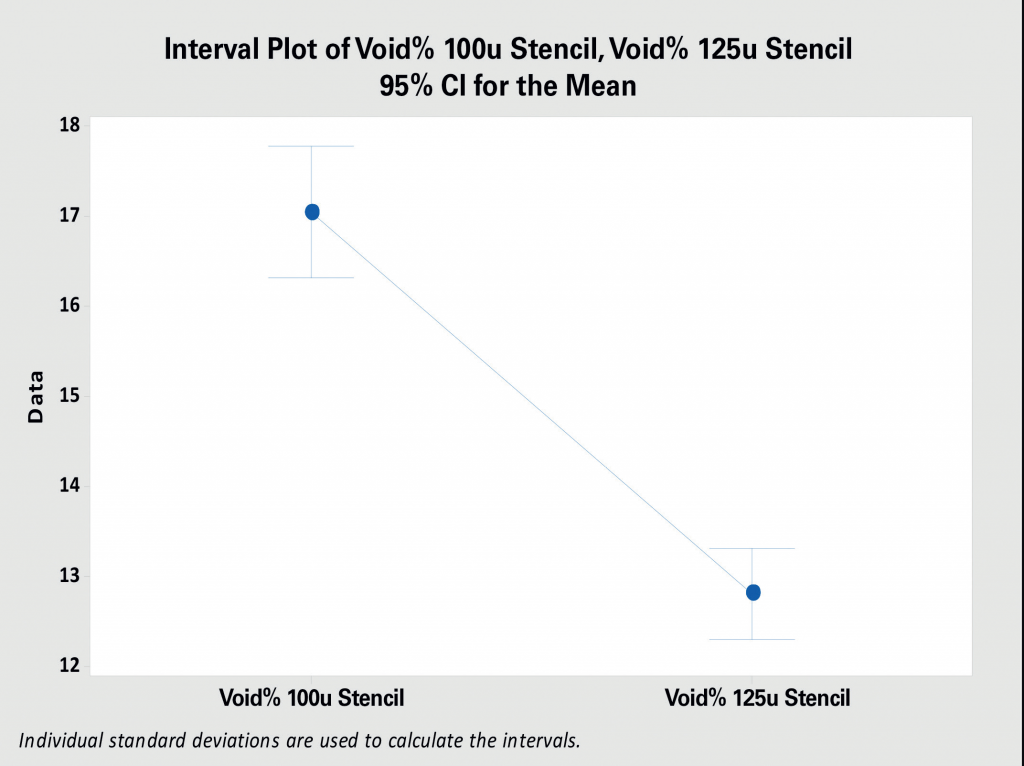

Using Profile #1 described above, voiding was compared between two stencil thicknesses of 100u and 125u. Figure 6 shows that the 100u print deposit exhibited more voiding than the 125u print deposit. This difference is statistically significant based on a Tukey analysis with 95% CI. We believe that the 125u print deposit exhibited lesser voiding because of the higher stand-off (compared to 100u) that allowed for easier outgassing/ venting of the solder paste flux volatiles.

Effect of Different Flux Chemistries on Voiding

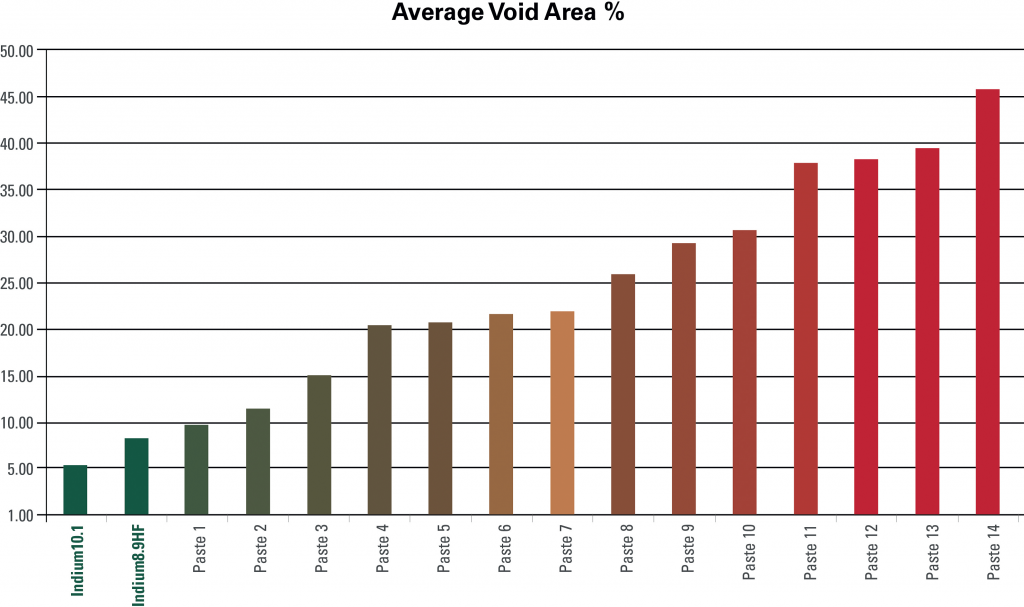

A final experiment evaluated the effect of 16 different solder paste flux vehicles (halogen-free as well as halogen-containing) on voiding. Three PCBs, with 12 QFNs each were used for each solder paste, with a total of 36 QFNs per paste. The results were striking, as seen in Figure 7. Some pastes consistently produced less than 10% voids, while others produced as much as 45%. These results were not only surprising, but also very encouraging. While voiding is a complicated process with many variables, selecting the optimum solder paste alone can ensure significantly lower voiding of less than 10%.

Summary

In this voiding study, it was found that all the three variables considered – (i) reflow profile; (ii) stencil thickness; (iii) flux chemistry type – had a significant effect on voiding. The hotter profile could reduce voiding due to expulsion of volatiles with higher vapor pressure, but it is critical to use the optimum flux chemistry with an enhanced oxidation barrier to counteract the effect of increased oxide with hotter profiles. The 125u thick stencil resulted in lesser voiding compared to the 100u thick stencil, because the higher standoff facilitated better outgassing of volatiles. The greatest surprise, however, was how significant solder paste formulations were in reducing voiding. The better solder pastes significantly reduced voiding to less than 10%, whereas the worst paste produced greater than 45% voiding.

Check out the interview with Karthik Vijay here.

Listen to the presentation live at

Budapest, May 25th, 9am – 5pm

Budapest, May 25th, 9am – 5pm

Register for FREE

Please use the registration code OLHUN17.