Having taken place mid-pandemic, Productronica 2021 attracted 894 exhibitors from 36 countries and about 20,000 visitors from nearly 70 countries. This may sound like a large number but, according to Exhibition Director Barbara Mueller, Productronica 2023 numbers are expected to instead reflect those from four years ago, in 2019 – when 1,500 companies from more than 40 countries exhibited, and over 44,000 visitors were in attendance. So what can they expect to see?

Mueller explained that, alongside overarching topics such as the shortage of skilled workers and sustainability, this year’s event will focus on power electronics, AI, sensors, and the second generation of quantum technologies. To reflect this, a programme of lectures and live demonstrations on these key areas will take place in Hall B2, Stand 448 in collaboration with the Productronics division of the VDMA, the conceptual sponsor of the event.

AI in AOI

The most important driver of AI technologies in electronics production is in the field of automated optical inspection (AOI). Repetition-based learning algorithms—systems have been in the process of replacing conventional IT for over a decade. ”Since the frequency of errors in electronics production is manageable, engineers have to create ‘artificial’ error patterns using image processing in order to achieve a more relevant learning sample for the AI and create an even greater learning effect,” explained Volker Pape, Chairman of the Board in the Productronics division of the VDMA, and co-founder of Viscom.

Almost all automated inspections systems in electronics production are now smart factory ready. Leading providers of AOI in Europe, including Goepel, Koh Young, Saki, and Viscom – all of whom are exhibiting at Productronica 2023 – are actively transitioning to using AI in their systems.

“Even without AI, two thirds of assemblies tested are classified as good,” Dr. Sebastian Mehl, whose task at Siemens is to integrate mature and working AI applications into production environments in electronics production, explained. “Of the around 30% that don’t pass the first time, only the smallest portion actually have an error. If humans undertook inspection for this number of false calls in the second pass, it would entail significant additional inspection effort. Moreover, there would be a high risk of several of the actual errors being overlooked.

”In SMT production lines at Siemens, the number of false calls has been halved, and the first pass rate increased by 15% with the aid of AI. The additional inspection effort that is no longer required can be tangibly measured in annual six-digit savings.”

Power electronics

Analysts from the Yole Group expect the global power electronics market to grow from USD 20.9 billion (2022) to USD 33.3 billion by 2028 at a compound annual growth rate (CAGR) of 8.1 percent. Governmental regulations, the expansion of renewable energies and the demand for energy-efficient solutions are further driving the trend.

According to Spherical Insights, the industrial sector currently holds a 24 percent share of the market as power electronics devices and systems become ever more widespread in motor drives, power supplies, robotics and process control. The growth of industrial automation is also an important driver in the expansion of this market.

Productronica exhibitors Rohde&Schwarz, Viscom, Löhnert, CRS Prüftechnik and SPEA will exhibit relevant solutions in this area.

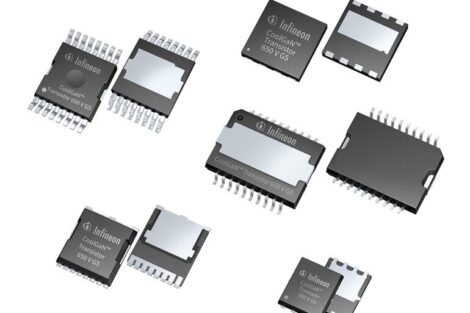

Silicon carbide & gallium nitride

The competitive cost/performance ratio of silicon makes it still the most widespread semiconductor material but it reaches its limits when higher operating frequencies and breakdown voltages are required. Because of this, components made of gallium nitride (GaN) and silicon carbide (SiC) are increasingly entering the field. Inverters based on wide bandgap semiconductors enable faster and lower-loss switching with significantly higher efficiencies. They are able to switch to higher voltages at higher frequencies—with less cooling required. Shorter switching times significantly reduce energy losses at are also able to tolerate more compact passive components such as inductors or capacitors.

Because of the lengthier and more complex manufacturing processes required, chips made from silicon carbide and gallium nitride are significantly more expensive than their silicon counterparts. However, manufacturers expect to reduce costs by switching to 300-mm wafer technology.

SiC in automotive applications

Silicon carbide offers significant advantages in power electronics applications in electric vehicles. More efficient and more compact drive and charging systems can increase a vehicle’s range and shorten charging time. In Hall B2, Stand 448, VDMA co-exhibitor Breuer-Motoren will present a SiC inverter power amplifier developed as part of the research project ”SiC-Mobil—SiC frequency converter for electromobility” as a test platform for investigating the reliability, service life, EMC and efficiency of fast-switching SiC power semiconductors.

Semiconductors

Co-located with Productronica, SEMICON Europa, one of the world’s leading trade fairs for semiconductor equipment, materials and services in Europe, will host the Advanced Packaging Conference and a forum on fab management.