There are many processes that utilize tolerances in industrial manufacturing and assembly that present significant challenges for users – even when performed manually. These include: assembly of components with incremental tolerances; handling of flexible parts; as well as end-of-line inspection of complete components.

Production processes in the above-mentioned areas usually require the calculation of tolerances in several dimensions, meaning simple measuring methods or mechanical solutions are not sufficient to automate them reliably. Few suppliers in the market offer the development of special solutions for these more complex measuring methods. And, as a result, automation potential remains untapped – despite a reasonable ROI. This is where intelligent software solutions, such as those offered by ArtiMinds Robotics, can really come into their own. Using a two-step process, these solutions ensure multidimensional tolerances are not a problem.

- The first step determines the relevant tolerances. The company’s software tools can be used with many different sensor methods to measure these tolerances.

- In the second step, data-driven improvement

of the automation system ensures better performance by reusing the measured tolerances.

Connector assembly

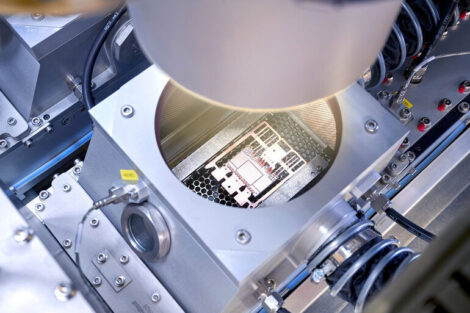

Since mid-2023, EBM-Papst has been using ArtiMinds’ software with three robotic solutions to manufacture blowers at its plant in Landshut, Germany. The assembly robots place printed circuit boards on a floating housing. The high tolerance process is performed reliably and promptly using the tolerance compensation features carried out via force-torque sensors. During commissioning, automatic data acquisition and analysis ensures that the results of this tolerance compensation can be assigned to individual workpiece carriers to improve them specifically – and benefitting other process steps in the system at the same time.

After the assembly process, two robots carry out an end-of-line test in which several connectors on the assembled floating board are contacted automatically. Tolerance compensation is also performed at this stage using the software tools, increasing process reliability. Due to the freely configurable connector position on the PCB, the robots must cover all angular positions across a possible 360 degrees, as well as different component variants. Cycle time requirements are met thanks to the TPO (Teach Point Optimization) software function. Based on the tolerance compensation carried out beforehand, this calculates a suitable teach-in point for each variant and angular position and makes this available to the robot via a PLC. In this way, the process automatically adapts to the tolerances of each variant and angular position after a few passes. Over the course of production, tolerances from other batches can also be integrated into the database. This learning process results in a robust production which avoids time-consuming readjustments when conditions change.

Cable handling

Automatic cable picking illustrates the challenges faced when handling flexible components. The software template library can be used to determine the gripping point and orientation of the gripper relative to the cable quickly and reliably based on a scan of the cable end. This allows for the implementation of a wide range of feeding types. To simplify such applications, the software allows standard sensors, such as 2D and 3D cameras as well as profile laser scanners, to be used in the robot program to automatically determine and compensate for tolerances.

In processes with high tolerances, such as cable handling, it is often necessary to conduct not just one but several measurements to determine all the tolerances. With a comparatively simple setup and low cost, profile laser scanners provide fast, highly-accurate 3D measurement along a line. Using the ArtiMinds library, profile laser scanner results can be processed directly on the robot controller without the need for an additional evaluation computer. In addition to data collection (i.e. triggering of detectors, received result and multiple result storage), the library also supports data processing. The latter covers a wide range of possibilities for novel automation solutions: from simple operators (like safety checks) to more complex operators (such as creating a scan from many measurements).

Force-controlled assembly

Thanks to the LAR analysis tool, the software can also retrieve and store process data from the robot controller during operation. This is timed to the programmed sub-processes, making analysis and monitoring easy. For processes with high tolerances, however, it is worth going one step further, and utilising automatic Teach Point Optimization (TPO). Here user interfaces mean data processing is standardized and access is simple. One of the greatest strengths of this feature is the wide range of filtering options offered. This makes it easy for the user to decide, for example, whether he wants to carry out optimizations per workpiece carrier, workpiece variant, or by batch.

An example of the LAR analysis tool in action can be seen in the automatic assembly of gears as implemented by Primus Präzisionstechnik using ArtiMinds’ software. This involves the production of small gearwheels from several individual parts: three shafts and five gearwheels within a gear housing. All parts are greased prior to assembly. This is a complex application with many process steps and different components and thus a high number of variants. It is important to note that Primus’ focus was not on optimizing cycle times during automation, but on increasing process and repeatability accuracy. The LAR analysis software provides detailed evaluations and data about the production process, based on robot movements, force-torque measurements, vision results or error codes. This makes it easy to identify potential improvements not visible to the naked eye. As a result, the manufacturer was able to adjust the accuracy of the application down to a one-hundredth of a millimeter and, after a few runs, re-evaluate whether the changes had the desired positive effect.

The advantages of these intelligent software tools when it comes to automating processes with tolerances are obvious. Even processes with high tolerances can be automated economically and without expert knowledge or extensive programming. The centralized use of tools and standard components means the resulting system concepts are very flexible and can be easily adapted to new requirements.