When developing automation and robotics solutions for use in the manufacturing of power semiconductor modules and electronics, the focus should be not only on the various processing stages but also on process control and parts handling. Often processes and production flow can be optimized simply by implementing custom transport and storage solutions. With this in mind, Sinergo has developed a range of customizable machines for use at various stages in the production of power modules. These solutions can be supplied either as standalone or as complete production lines. They cover:

- Dividing: to divide the DCB Mastercard into single DCB modules output

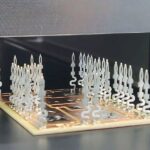

- Soldering: electromagnetic induction soldering of the pins in the DBC module. The use of induction instead of the oven saves time and reduces costs.

- Boxing – gasketing & potting: Casing modules by edge sealing, silicon filling mono/bicomponent …

- Polymerization: UV and or heat curing;

- Testing and marking: comprising static testing hot & cold, HV insulation testing, laser marking, weighting, class sorting, and more

- AOI quality inspection and measurement

Producing power modules faster

The company’s automation technology for the soldering of signal and power leads onto ceramic substrates differs significantly from traditional methods. Thanks to our new technology, this can now be achieved without an oven, without the use of hundreds of fixtures and without the need to wash the modules and the jigs afterwards, enabling an uninterrupted production flow – from the first step (substrate with die and bonding) to encapsulation, test and labelling. The company’s equipment also offers several other advantages:

- The production process is contactless, meaning a reduced number of workers are required to run the line. This enables a cleaner process, without risk of damage caused by operators.

- The machine is ready to go without any warm-up time meaning no time is wasted.

- The process is energy-saving because the localized heating is on the interested part only and the “washing phase” has been eliminated

- Control, traceability and measurement are performed on modules that have been manufactured using Sinergo’s automation equipment.

Boxing- gasketing & potting solution

After the signal & power leads have been soldered onto the substrate, the ’boxing’ phase begins. The company also offers automation solutions in this area, facilitating, among other things, inlet and outlet pick & place, AOI and measurement, assembling, gasketing, UV curing, mono and bicomponent potting, weighing and testing functions. These machines are usually specially designed and constructed according to a customer’s specific requirements. We have also recently introduced standard mono and bi-component automatic dosing cells suitable for various applications including in the production of high-power inverters for e-mobility. Among the most important features of this equipment are:

- Two independent pumping units and vacuum degassing systems which are embedded meaning the footprint is greatly reduced

- Volumetric dosing that is fully programmable via a user-friendly HMI

- Process control

- Self-adjusting dispensing path due to the laser measurement of nozzle position

Optimising handling procedures

One thing all machines of the company have in common is their compactness. By optimizing parts handling procedures, the company manages to save space wherever it can. Based on the needs of each customer and sector, different methods are used, and hardware is tailored to suit different functions, allowing for improvements in transportation and storage within each machine. The goal is always to save both time and space, and achieve greater quality, efficiency and cleanliness overall. Extending automation solutions to the handling of parts also enables greater control and reduces the number of errors that occur during processing. The modular design of the equipment allows for different production line configurations and helps facilitate future modifications or improvements. To optimise handling procedures, a wide range of transport systems are deployed to improve the flow of the pieces being processed on the production line. These include:

- Compact pallets optimized in terms of size, characteristics and circulation modes (for instance, external ring, internal ring, internal circulation with lifters and lower passage)

- Handling systems with mechanical feeding with circular, linear and jolting vibration

- Mechanical-optical singulation with robotic-picking guided by machine vision system

- Electronic rotary tables

- Mixed systems combining cartesian robots with robotic arms

- Working “on fly” pieces that are on the wrist of the robot

- Vacuum gripping systems using force control, torque control and profile tracking that interact with other actuators

- Custom carriers, magazines, connection belts, “pilgrim-step” actuators, self-adjusting size grippers

HMI: the man-machine interface

Sinergo’s aim is to increase automation in processes where it has not yet been fully implemented, such as in the production of semiconductor modules in which much of the assembly, loading and unloading is still carried out manually. Automation solutions in these areas change the operator’s role and drastically reduce their manual involvement in the process, effectively turning them into a ’plant manager’ who may only use the interface remotely. This ensures cleaner, safer, and fully traceable processes at all times.

Each of our products offers a well-designed Human Machine Interface. Our staff design the HMI to match each individual customer’s request – as well as the specific needs of the operators. We offer large monitors, intuitive messages, simple yet detailed instructions and modern graphics in a user-friendly style.

Our HMI typically provides these main functions:

- Access management with password and different levels, fully configurable by the customer

- Programming functions for plant use

- Automatic and manual operating modes with real-time visualization of everything that happens (including video)

- Control windows to manage all the actuators and robots

- A control page for all subsystems and sensors

- A dedicated page for both local and remote diagnostic functions

- Comprehensive traceability and data logging functions related to both products and the plant

- Database SW structure implemented to handle data, pictures and videos including storage (NAS)

Cleaner processes with no human contact

Combined, our equipment, optimized processes and automated parts handling result in an efficient production flow untouched by human hands. This is positive not only in terms of efficiency – it also reduces the risk of contamination, as well as of ESD and mechanical damage.

Zusammenfassung Résumé Резюме

Der Artikel stellt neueste Automatisierungs- und Robotiklösungen für die Produktion von Leistungshalbleitermodulen und -elektronik vor und betont die Vorteile einer Produktionslinie, die ganz ohne menschlichen Kontakt auskommt.

Cet article présente les solutions d’automatisation et solutions robotiques les plus récentes permettant de produire des modules et des composants électroniques pour semi-conducteurs de puissance et met en avant les avantages d’une chaîne de production qui se passe complètement de contacts humains.

В статье представлены новейшие решения в области автоматизации и робототехники для производства силовых полупроводниковых модулей и электроники, а также подчеркнуты преимущества производственной линии, которая функционирует без какого-либо человеческого вмешательства.