Delivering both on time and cost-effectively is ever more challenging in the highly-competitive industry that is SMT manufacturing. Despite delivery within a week having been common not so long ago, customers are now stipulating that deliveries take place on specific days – and at the same time ordering multiple different products in small lot sizes. Meeting these new demands requires exceptional flexibility and efficiency – particularly as cost-related pressures are also rising.

Production planning – a highly complex task

Now more than ever, success depends on intelligent and networked production planning that considers the requirements of both the customer and the manufacturing line. The goal is to maximize utilization of existing production capacities while

minimizing interruptions and setup changeovers. By this point, the planning process has become a highly complex task in which order production sequence plays a vital role. A simply switch from lead-containing to lead-free solder paste, for instance, will interrupt production for up to 30 minutes while the

reflow oven heats up or cools down to cater for different melting points. For this reason, it makes sense to run orders requiring the same type of solder paste consecutively on a line. Moreover, some lots require X-ray inspection for ball grid arrays while others involve odd-shaped components (OSCs) that must be placed with the TWIN placement head – requiring special equipment not necessarily available on every line. Even this relatively simple example which considers just three critical factors demonstrates the central problem: namely, that individual requirements overlap and influence one other. Add to this the fact that there may be line clearances for certain products, as well as other factors, and you are left with a highly complex, multidimensional matrix with countless possible variations – and only one optimal solution.

Dependency on individual specialists

In factories that plan manually, the quality of scheduling still depends largely on individual employees. These are usually specialists with years of experience who know both the products and customers very well. This fundamental dependence on specific employees often becomes a problem, particularly in locations where the company-employee bond is less pronounced than in Germany. When a qualified scheduler leaves the company, there is a loss of very specific know-how that can affect the whole production. The shortage of skilled labour also makes it difficult to find suitable replacements.

Software developed by practitioners for practitioners

When new products are introduced, even long-term and highly experienced employees can no longer keep track of the entire process matrix. It thus makes sense to automate the planning process. This is easier said than done however. To develop a new software product, you need to be familiar with the conditions and processes of modern SMT production while also taking individual freedoms into account – after all, no two factories are alike. Those who are purely software developers often fail to do this because they lack the necessary experience.

But ASMPT is different. The renowned global player covers almost the entire SMT production process with its product portfolio and is intimately

familiar with the requirements of modern production lines as a result of its close customer relationships. After defining the functional specifications in minute detail, the technology leader opted for a two-stage planning concept and implemented it in the workflow planning of its WORKS Software Suite.

Workflow for rough and detailed planning

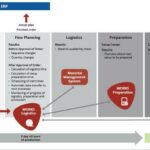

WORKS Planning elegantly reconciles the requirements of customers and production specialists. The software initially creates a rough plan three to five days before production begins. First, the order data is imported from the ERP system. The rough planning routine adopts defined priorities by considering the resulting orders in a precise order. It starts by looking backwards from the promised delivery date. If this date cannot be met due to resources being already occupied, the system searches automatically for alternative resources that are available, and creates a forward-looking plan which maximizes setup efficiency. This rough planning process focuses exclusively on customer requirements.

From the factory‘s perspective, however, planning that is purely customer-oriented is not always feasible as material bottlenecks or resource shortfalls may necessitate last-minute changes in the production sequence. This is where the detailed planning stage comes into play. This begins roughly one to two shifts in advance of the planned production start. Here, production tasks are assigned to specific lines and corresponding processes such as inventory retrievals and setups are scheduled to ensure the next production round begins on time. The WORKS Logistics application develops a plan that optimally combines production specifications and deadlines to make the best possible use of existing production equipment. When the lots are finished, they can even be automatically reported back to the ERP system.

Intelligent factory as overarching concept

That all this works so well is thanks to ASMPT’s holistic and data-driven intelligent factory concept, which relies on data from lines spanning the entire factory. All the information that is generated in the factory is collected, processed and linked via standardized interfaces in order for it to be put to targeted use in various applications including quality management, fault analysis, effective staff deployment, seamless material flow control, and optimized workflows (such as the planning process described above).

ASMPT has integrated this complex planning functionality within an easy-to-use, ergonomic user interface in which even newcomers can achieve optimal results. WORKS Planning and WORKS Logistics achieve an important goal: namely, removing

planning tasks from a dependence on specific people, and thus allowing them to be easily scaled up to new locations. The implementation of the suite is usually rapid and glitch-free. If any functional gaps are discovered, the ASMPT team can quickly close them with software extensions.

Faster, easier, more efficient

“In practice, the advantages of the new system become apparent very quickly,” says Mathias Heinz, Product Manager at ASMPT. “The software optimally supports the planner in the needs-based alignment and pooling of orders, for example into family setups. The automated workflow makes it possible to simulate and analyze multiple combinations much more quickly than before. Electronics manufacturers are often amazed at the untapped potential slumbering in their equipment,”

Considering a modern SMT factory changes the setups on each line five to six times a day, it quickly becomes apparent just how much time can be saved simply by taking a process attribute like lead-free or lead-containing solder paste into account. Experience shows that the number of setup processes can be reduced by 20% or more. Data-driven planning alone can accommodate additional orders without requiring an investment in new hardware.

There are also significant savings to be made in the area of human resources. The planning of 150 to 200 orders per week was once a full-time job; now, the person who was responsible for this can focus on other duties.

Last but not least, more accurate planning improves the adherence to deadlines, which benefits subsequent workflows and ultimately the customer. “With WORKS Planning, ASMPT raises electronic planning and scheduling to a whole new level. It is the first software that has managed to map and optimize the complex planning process in SMT manufacturing. Put simply: WORKS Planning makes our customers’ lives much easier,” says Heinz.

PCIM Europe, Stand 6.450