Supplier of electronics production equipment, Kurtz Ersa, will exhibit in Booth 1301 at the IPC Apex Expo 2023, scheduled to take place 24–26 January 2023 at the San Diego Convention Center in California. The manufacturer will give customers in depth and personalized equipment demonstrations for wave soldering, reflow soldering, selective soldering, rework equipment, hand soldering, additive manufacturing, I4.0 connectivity and more. It will also highlight the i-CON Trace soldering station, Versaflow One selective solder system, EXOS 10/26 reflow soldering system with vacuum, HR550 XL with auto scavenging and ALPHA 140.

Traceable hand soldering

The i-CON Trace is an IoT soldering station that enables seamless traceability during manual soldering. With integrated WLAN, Bluetooth and network card on board, the station already offers 100 % connectivity in digitally networked manufacturing processes when delivered. The possible MES connection allows the integration and storage of soldering parameters used in complex, networked manufacturing processes that already run via an MES. The system impresses with maximum performance and minimum operating costs. With 150 watts of power, it heats up quickly, reheats even faster and can be controlled extremely precisely.

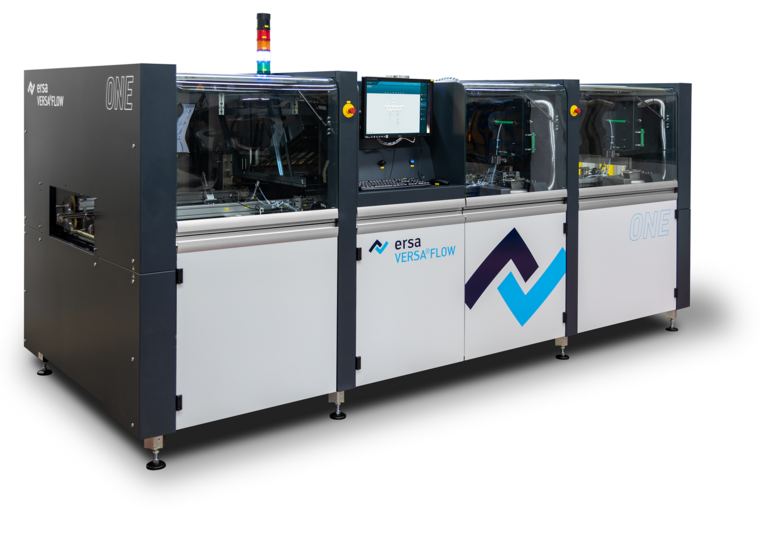

Selective soldering machine

The Versaflow One incorporates decades of know-how in the form of proven hardware and intuitive software (ERSASOFT 5). Set up, switch on, solder – optimal selective soldering could not be faster or easier. With the highest demands on quality, throughput and ease of maintenance. In addition, the machine scores with the highest availability world-wide and a delivery time of about two to four weeks.

Hybrid rework system

The HR 550 XL features a 1,800 W high-performance hybrid heating element that can be used to desolder and solder SMT components up to the size of 70 x 70 mm. The 6,400 W infrared bottom heater with eight zones ensures homogeneous heating of the entire assembly. The hybrid rework system is for all users who place the highest demands on precision and safety when reworking large assemblies.

Booth 1301