Viscom AG announced plans to introduce the virtual inspection, 3D Planner, at the productronica electronics trade fair, from Nov. 14–17, 2017 in Munich, Germany. With this newly developed software tool, a wide range of inspection scenarios can be tested and evaluated off-line. This virtual inspection simulator uses CAD and 3D data from the printed circuit board and determines the optimum inspection concept. It provides companies in the electronics industry with a timely planning aid because the inspection coverage can be determined early in the development phase of new printed circuit boards (PCBs) or when planning the production process.

For example, the simulator shows the user how long inspection of an electronic assembly would take with the currently planned inspection program and where weak areas in the inspection coverage are apparent in the layout. This makes the off-line tool helpful right at the beginning of the process chain, such as when a PCB designer or production planner wants to know the effort involved in inspecting a new product in the production line. „The 3D Planner virtually simulates the inspection process,” explains Detlef Beer, Senior Manager in Product Engineering. “With it, whether the entire inspection coverage is good, sufficient, or incomplete, is quickly recognized without having to create an inspection program for the optical and X-ray inspections in advance.”

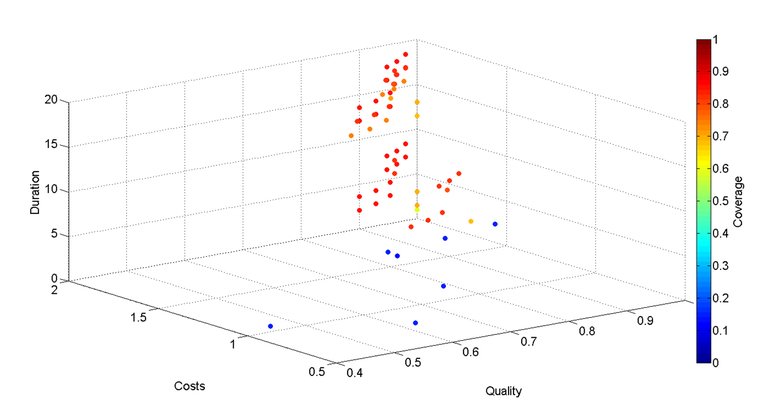

With this software tool, the proportion of orthogonal, angled, and 3D inspections can be tuned to one another. With the inclusion of the optical inspection methods, the X-ray inspection can be overall optimized and reduced to the reasonable minimum. This significantly reduces radiation load on individual components. At the same time, the entire inspection process is optimized. Inspection coverage, inspection quality, throughput speed and costs can be individually weighted in the simulations to suit the application. The 3D Planner allocates the ideal proportion of tasks to the inspection gates for automatic optical inspections (AOI) and X-ray inspections. Detlef Beer adds: „The benefits show their full strengths when used on the X7056 combination systems from Viscom for especially efficient 3D AXI and 3D AOI inspections.“

In the future, the software will also use 3D CAD models with components and leads, so that a complete, virtual reproduction of the PCB is already available in the planning stage. This type of data is currently under development at the suppliers‘ and, as soon as it is ready, will be applied in the 3D Planner. Until that point, along with footprint and Gerber data, overview images and 3D information from the PCB as otherwise used during 3D off-line program creation for AOI will serve as input. The inspection simulator is based on the modern vVision operating software.

productronica, Booth A2.177