CyberOptics Corporation, a developer and manufacturer of high-precision 3D sensing technology solutions, will demonstrate the SQ3000-DD 3D Automated Optical Inspection (AOI) system with the new ultra-high resolution Multiple-Reflection Suppression (MRS) sensors at productronica 2017. The company will also unveil the SE3000 3D SPI and SQ3000 3D CMM, both powered by MRS technology.

The SQ3000-DD 3D AOI dual lane, dual sensor system maximizes flexibility catering to varying PCB widths. This unique design provides the ability to inspect high volume assemblies, the convenience of inspecting different assemblies and board sizes simultaneously on different lanes, or even switching from dual lane to single lane mode to inspect very large boards.

Not only does this AOI system provide the PCB inspection flexibility, it also provides the flexibility to choose two of the same or two different proprietary MRS sensors, both of which meticulously identify and reject multiple reflections caused by shiny components and reflective solder joints.

The new ultra-high resolution MRS sensor option provides an even finer resolution than the standard, delivering superior inspection performance ideally suited for 0201 metric and microelectronics applications where an even greater degree of accuracy and inspection reliability is critical. The unique architecture of both MRS sensor options simultaneously captures and transmits multiple images in parallel, while highly sophisticated 3D fusing algorithms merge the images together, delivering microscopic image quality at production speed.

The SE3000 SPI system is the first SPI system to incorporate the MRS sensor technology with a finer resolution for the best accuracy, repeatability, and reproducibility – even on the smallest paste deposits. Combined with the easy-to-use software, solder paste inspection has reached a new level of precision for the most stringent requirements.

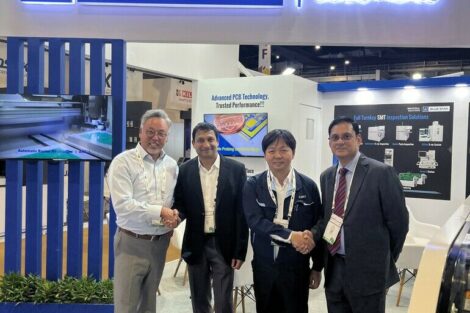

“We’ve incorporated our MRS sensor technology into multiple platforms for AOI, SPI and CMM,” said Dr. Subodh Kulkarni, President and CEO, “Providing our customers with the best combination of accuracy, speed and ease-of-use to maximize their yields and productivity.”

The SQ3000 3D CMM (Coordinate Measurement) system, powered by Multi-Reflection Suppression (MRS) technology utilizes CyberCMM, a comprehensive software suite for coordinate measurement. In a lab or production environment, the system is fast and highly accurate, with repeatable and reproducible measurements for metrology applications in manufacturing of a wide variety of products such as PCBs, semiconductors, and consumer electronics.

This software is an extensive suite of CMM tools, provides 100 percent metrology-grade measurement on all critical points much faster than a traditional CMM, including coplanarity, distance, height and datum X, Y, to name a few. A fast and easy setup can be performed as compared to a slow, engineering resource-intensive setup that typically requires multiple adjustments with traditional CMMs.

productronica, Booth A4.239