Koh Young Technology will exhibit at the upcoming SMT Hybrid Packaging show scheduled for June 5–7, 2018 at the Messe in Nuremberg, Germany. Under the slogan, “True 3D Smart Factory solutions powered by the AI platform,” the company will display the next-generation Zenith2 3D AOI, new KY-P3 3D pin inspection solution, and the automated solder dispensing feature on its KY8030–3 3D SPI.

Latest AOI system

The company will demonstrate its Zenith2 3D AOI, which inspects a wide range of components with side-view camera solutions. This user-friendly, smart 3D AOI was designed with Industry 4.0 in mind. Some new features include AI-powered Auto Programming, which automatically configures inspection conditions and yields a 70 % reduction in programming time and OPO@KSMART (Offline Program Optimizer) to automatically define and deploy modified inspection conditions without interrupting production.

3D SPI with auto-repair

Also on display will be the enhanced 3D SPI system with an innovative integrated solder paste dispensing function called Auto-Repair. The high-precision, user-friendly dispensing system helps to eliminate costly mistakes from insufficient solder that contributes to open joints, lean fillets, and weak joints. While the KY8030–3 inspects solder paste with the highest possible speed and precision, it can now repair insufficient solder defects before leaving the machine. With this new feature, manufacturers realize an enhanced first pass yield and reduced operational costs.

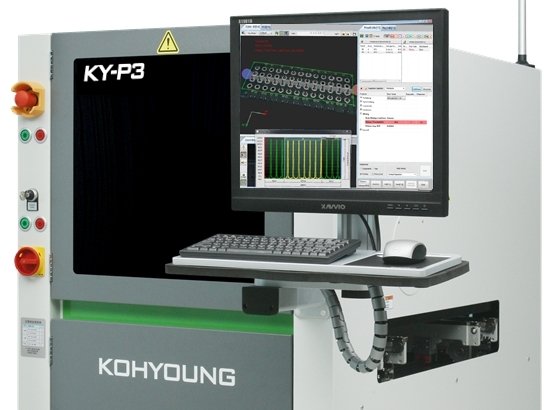

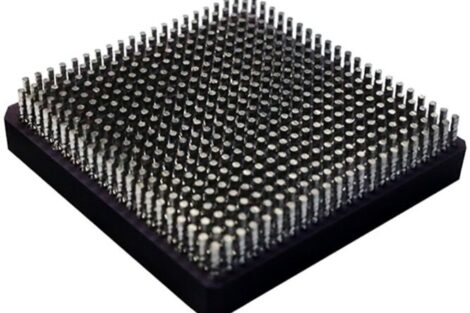

Pin inspection system

Leveraging its strength in robotics and 3D measurement, the company will also highlight the KY-P3 inspection solution. This machine allows manufacturers to measure and inspect a wide range of pins, including single pin, press-fit, fork-pin, and connectors. Using 3D measurement, it ensures the pins are correctly aligned for the designated through-hole openings in the circuit board. It also uses the company’s 3D imaging technology, which measures with ± 0.75 % pin height accuracy.

SMT Hybrid Packaging, Booth 4A-233