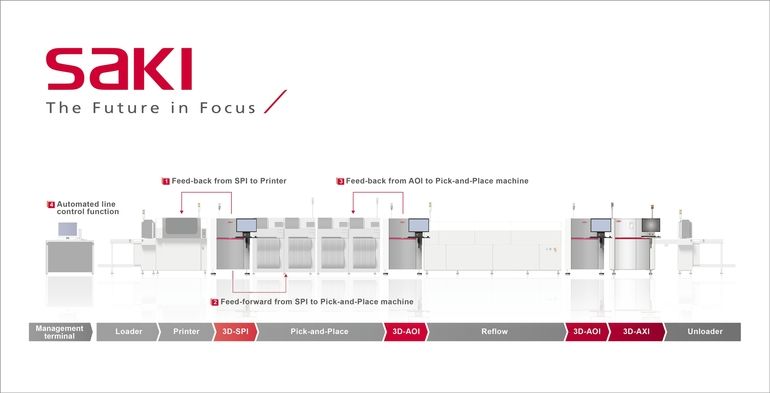

Saki Corporation, an innovator in the field of automated optical and X-ray inspection and measurement equipment, will demonstrate automated inspection products, software, and capabilities and announce new personnel, offices, and collaborations at IPC Apex, San Diego, CA. On display will be a combination 3D automated optical inspection (AOI) with 3D solder paste inspection (SPI) system, an automated X-ray inspection (AXI) system for printed circuit board assemblies (PCBAs), new self-programming software with self-tuning, and advanced M2M capabilities.

Saki‘s combination AOI/SPI system fits NPI, high-mix/low-volume, and high-volume applications, enabling all companies to use both SPI and AOI inspection to ensure the quality of their manufacturing process and products, even when using 01005 and 0201 metric components and board sizes up to 27 “ x 34 “. Multiple sensors of 7 μm, 12μm, and 18 μm accommodate the inspection needs of almost all manufacturing operations. Common software and a common user interface enable the company’s SPI, AOI, and AXI results to be viewed together, and programming is easy and intuitive, taking minutes instead of hours and providing automated data analytics and line performance dashboards.

Saki‘s 3Xi-M110 3D-CT AXI machine for printed circuit board assemblies ensures the quality of hidden solder joints for bottom-electrode packages such as BGAs, LGAs, QFNs, flip-chip, and package-on-package and provides precise volumetric measurements and shape reconstruction to find voids, head-in-pillow, and other defects that are difficult to identify. The X-ray tube reduces X-ray exposure up to 70 % by powering the X-rays on only at the moment of image capture. The tube doesn‘t need periodic maintenance or spare parts and the system reports when the tube needs replacing. The company’s system delivers high-resolution from 10 μm to 30 μm. The 3Xi-M110 is 40 % lighter and 25% smaller, saving floorspace. Image capture speed is increased by 30 %, reducing production-line takt time.

Saki‘s new software solutions include its QD Analyzer which it co-developed with Cogiscan. This advanced software for manufacturing production quality and control presents actionable KPI data to accurately identify the cause of defects based on inspection results, while simultaneously monitoring machine performance and collecting traceability data. The software includes a defect-analysis dashboard detailing line performance, including drilling down to the exact pin of a reference designator to discover exactly what‘s hindering productivity.

„IPC Apex will be a chance to introduce Saki America‘s new personnel and offices,“ said Norihiro Koike, president. „Saki technical experts from Mexico, Brazil, and Japan, as well as the United States, will be available to assist with your inspection needs. Please visit our booth at IPC Apex 2020.“

Apex, Booth 2025

Company contact

Saki Corporation

DMG MORI Tokyo Digital Innovation Center

3–1–4, Edagawa, Koto-ku, Tokyo 135–0051 Japan

Tel. : +81 3 6632 7910

E-Mail: pr@sakicorp.com

Website: www.sakicorp.com