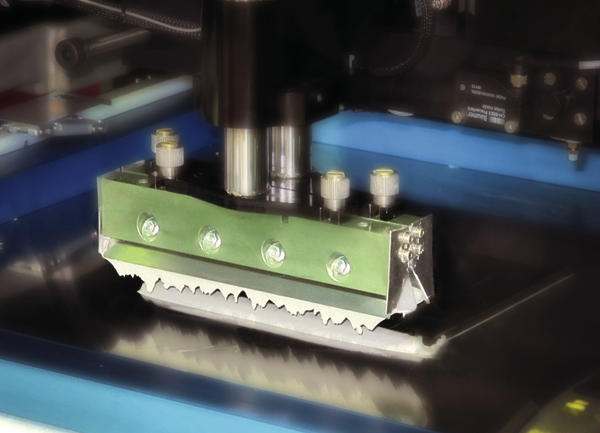

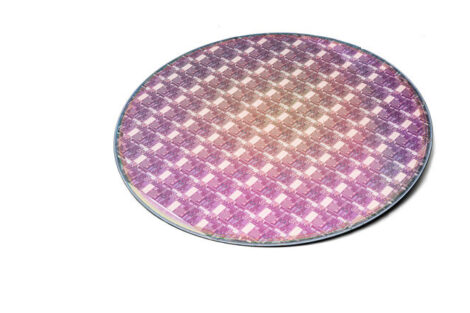

Never content to rest on the laurels of its proven lead-free success, Henkel has developed and launched Multicore LF620: a new lead-free solder paste that effectively delivers on a broad range of demanding requirements, essentially offering a lead-free paste that has it all. This latest product from the global ma- terials leader is a no-clean, halide-free, Pb-free solder paste that has a broad process window for printing, reflow and humidity resistance. In fact, the rigorous engineering at the foundation of Multicore LF620 ensures its consistent print performance with minimal hot slump even in regions with temperatures of 30 °C (86 °F) or more and relative humidity (RH) upwards of 80 %. This makes Multicore LF620 well-suited for electronics firms that wish to use a single material for their worldwide operations, as its performance is unfailing regardless of extreme climate changes. Formulated with a new activator chemistry, Multicore LF620 exhibits extremely low voiding in CSP via-in-pad joints, good coalescence and excellent solderability over a wide range of surface finishes includ- ing Ni/Au, Immersion Sn, Immersion Ag and OSP copper. In addition, the material’s versatility delivers outstanding printability at low or high speeds, with brick- like print definition, yielding vast improvements in throughput while also ensuring consistency of print deposits. „The capabilities of Multicore LF620 make it the ideal choice for manufacturers of today’s highly miniaturized devices,” explains Dr. Mark Currie, Henkel Global Product Manager. „For multi-functional complexly populated boards and for smaller handheld devices that dictate finer-pitches (0.4 mm and above), reduced board sizes and in- creased functionality, Multicore LF620 offers unmatched performance and processability.” In addition to the handheld market, Multicore LF620 is very well suited for the automotive sector, as the material has a wide reflow process window accommodated by its robust flux system. Process flexibility is also superb with Multicore LF620, which delivers a high tack force for component stability during high speed placement, an abandon time of four hours and a market-leading print work-life of up to 24 hours with no degradation in print quality.

SMT/Hybrid/Packaging

Booth 9-353

Share: