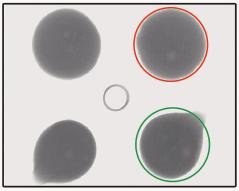

With the Viscom high-speed 2D BGA Analysis, defects on advanced packages such as BGA, µBGA, CSP, etc. can reportedly be detected automatically and reliably. Lifted leads are also no longer a problem using a non-circular pad design. This way, time-consuming 3D inspection is no longer necessary. Frequently occurring defects include formation of bridges, voids or pores, off-set and twisting. The automatic analysis tool simplifies inspection considerably, and is accomplished in four steps. Lifted leads are a special case and as such are difficult to detect. Until now, attempts were made to solve this problem with the aid of 3D X-ray technology. Though the use of 3D is practical for applications where defect recognition is no longer possible using 2D, it does not provide any advantage in inspecting BGA solder joints due to the increased time. By using the non-circular pad geometries, it is only necessary to change the pad design, eliminating expensive inspection procedures. Studies on the long-term characteristics and reliability reveal that non-circular pads are equal to standard solder connections. Tests have also confirmed that identical X-ray spectrums are present for lead-free solder connections.

EPP EUROPE 444

Share: