ERS electronic GmbH, a leader in the market of thermal test solutions for semiconductor production, is introducing two new innovative products. The systems are targeting the thermal debonding and warpage adjusting in eWLB (embedded Wafer Level Ball Grid Array) processes for 300/330 mm wafer processing. With their innovative features, these machines enable semiconductor manufacturers to increase both throughput and yield.

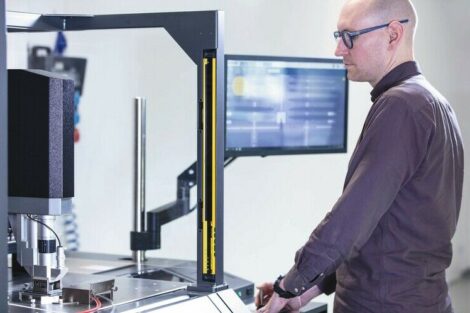

The ERS ADM330 is designed for the thermal debonding of eWLB style wafers without human intervention at high precision and with unmatched repeatability, resulting in high and predictable process quality and thus guaranteeing high yield. The two handling robots accept wafers with a maximum warpage of ± 5 mm; after the adjustment step, the warpage is typically less than 500 µm.

With built-in OCR/BCR capabilities, the ERS ADM330 allows for automated exchange of batch parameters with process control systems through its optional SECCS/GEM interface. This enables operators to drive integration into higher-level factory IT systems one step further. Its integrated laser-scribing chamber allows for continuous and complete monitoring of production-relevant data.

The ERS WAT 330 is a fully automated warpage adjust tool for 300/330 mm wafers that can handle up to four FOUPs concurrently. With its specially designed proprietary Warpage Adjust Technology, also included in the ADM330, this system can form a wide variety of eWLB wafers at various processing stages. The resulting wafer shape can be matched to the handling specifications of the downstream tool.

Its three operation modes give users of the ERS WAT 330 a maximum of flexibility in high-volume production environments. The system can be used as a warpage measurement station, as a warpage adjust station or as a combined tool to measure, adjust and monitor warpage. In warpage adjust mode, the system can reduce wafer warpage from ± 5 mm to below 500 µm.

Meeting the SEMI E84 interface specifications for factory automation, both systems are future-proof with respect to next-generation digital factory concepts.

Share: