With its E by Siplace platform, ASM will introduce an affordable and extremely flexible placement solution for small lots and prototypes and for small to medium-sized plants. The concept was newly designed from the ground up and features many functions and technologies that machines in this segment have never offered before.

With its E by Siplace, ASM is entering the broad target market below the premium segment by offering an all-round solution for the many applications that don’t require a high-end line. The fact that ASM developed the new platform from the ground up demonstrates the Munich-based manufacturer’s long-term commitment to this new platform. The company even set up an own sub-division, a special E-team, for this new machine platform. “Since we gave this team a totally free hand, the members could focus fully on the development of market-appropriate solutions for a wide range of applications. They surveyed customers all over the world about their wishes and requirements. They had access to Siplace’s know-how, of course, but were free to develop their own concepts and solutions,” says Sven Buchholz, who heads ASM’s E by Siplace department.

What makes the new machine special?

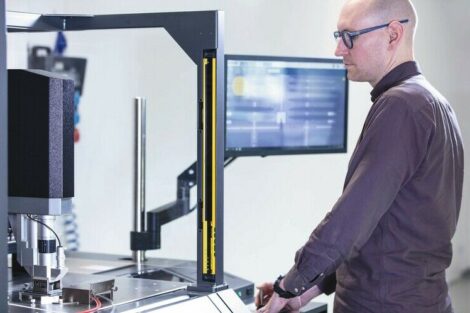

The new machine exemplifies the benefits of this approach. The solution is not a stripped-down high-end machine, but a fully independent platform. It differs from competitors’ models in at least three areas: its placement quality, its real-life performance, and a web-based support concept that provides electronics manufacturers with a totally new range of possibilities.

“Users tell us that the existing solutions in this segment are not keeping up with the steadily rising demand for placement quality. The second critical point is everyday performance shortfalls, mainly due to long set-up and preparation time between different production orders. We want to set our E by Siplace apart with significant improvements in quality and performance apart. Our service and training are also embarking in new directions, because the Internet opens the door to new concepts that offer huge potential savings in terms of operating costs and reaction time,” says Buchholz

Scoring with quality

The platform achieves process reliability and repeat accuracy with its quality-oriented choice of vision systems, drives and placement heads. For example, all axes on the new machine are controlled with highly accurate and low-maintenance linear drives. In combination with excellent controllers and high-quality sensors, these drives provide the basis for a level of placement accuracy that is uncommon in this price and market segment.

Every E by Siplace comes with placement force sensors and a high-end vision system

The vision system promises top quality as well. The machines come with the same high-resolution digital vision technology that the brand employs to set standards in the high-end segment. Component-specific illumination settings, single shots of each component and super-fast image analysis algorithms are features that no one else offers in this segment.

Most all-round applications operate with a broad component spectrum, ranging from large components and connectors that must be placed with lots of force to many small, highly sensitive components. And when the substrate is subject to warping, things become even more complex. All ASM machines are therefore equipped with placement force sensors by default – a feature that will be welcomed by many electronics manufacturers.

Clever all-round solution: Combi heads for single-gantry

models

To cover a broad range of applications, the platform offers a comprehensive portfolio of placement heads. The CP14 placement head is a high-speed head with 14 individual nozzles, which can – without any additional options and compromises – place components ranging from 01005 up to SO8 with exceptional performance. Especially manufacturers of sensors, flexible substrates and medical applications will highly appreciate this.

Since it is a single-gantry machine, one might assume that it will always take at least two machines in a production line to cover a standard component spectrum. But ASM’s E-team had a different idea. To keep costs down, they combined a fast collect-and-place head with a flexible pick-and-place head. These can handle components ranging from 01005 to 45 x 98 mm and a height of up to 19 mm. Despite this very broad spectrum, the CP12/PP achieves a very high speed rating of 24.200 cph. In short, the combi-heads are ideal solutions for electronics manufacturers who want to use a standalone E by Siplace machine as an all-round solution for short runs or prototypes. For odd shapes and large components with edge dimensions of up to 200 x 110 mm and heights of up to 25 mm, the solution also accommodates the proven TwinHead of the company – the solution for unusual requirements.

Components are supplied via E-feeders, which are very similar to the high-end feeders. Their highly reliable tape guides and precise motors make sure that every part is fed with exceptional precision and repeatability. They calibrate themselves, are robust and require very little maintenance. This process chain of highly accurate component supply, high-resolution and speedy vision systems, intelligent head combinations and linear drives provides the new platform with high real-life performance even for complex products with very small and/or very large components.

While its technology is impressive in itself, the new platform features a lot more, because the E-team is also going new ways in sales, support, training and service.

Easy operation and innovative web services

Electronics manufacturers are always on the lookout for robust solutions that are easy to operate even by new and semi-skilled workers, which is why the E-team placed great emphasis on this aspect. Thanks to software wizards and a comprehensive component library, describing a new component takes only a few clicks. All the user has to do is follow the instructions on the screen. And all line and/or machine functions can be programmed directly on the machine – without having to interrupt the production flow.

In addition to simplifying the software and user interfaces, the E-team also decided to break new ground with regard to training, instructions, and a whole lot more. On www.EbySiplace.com, registered customers will have access to a portal with videos and interactive instructions as well as checklists that can be printed out. That way, employees can learn wherever and whenever they want. New product introductions? Efficient planning of production and setup processes? Machine maintenance? Users will find instructions for these any many more applications, also in the form of easy-to-follow videos.

“Similar successful web-based service concepts already exist in many other industrial and consumer fields. We want to consistently promote this concept with the platform in order to make web-centered services a unique selling proposition for the new line. Since many small and medium-sized companies and their employees have a true can-do mentality, our web offerings will help them make the most of this strength. This will virtually eliminate the need for external manufacturer services, thus reducing the customer’s operating costs to a minimum,” says Sven Buchholz.

A strong presence with many new ideas

Statements like “We want to become as successful in this market as we are in our traditional premium segment” make it abundantly clear what ASM Assembly Systems wants to achieve with its E by Siplace. The company has obviously paid attention to many small and medium-sized producers and developed new and innovative approaches for this market. With this platform, the company is adding not only a newly developed placement platform, but also new service offerings to its traditional focus on the premium segment. The future belongs to the Internet, and services for electronics productions are no exception. ASM’s idea to create a separate E-team in addition to the existing (high-end) organization and give them lots of freedom provides the project with plenty of momentum. And having a new player in the all-round segment means that things will get quite exciting.

Share: