No doubt, the Munich-based Productronica turned out to be a success story. Almost 43,000 visitors came to the Bavarian capital. 38 % were from abroad (16,213 from 87 countries), and more than 1,500 exhibitors were present. The globally important event was well attended, and, best of all, revealed clear signs of confidence in the long-awaited upturn in the electronics business.

This now seems to be the right moment to get into fresh projects, since recovery in the global electronics business is becoming a fact. As it always is, the first indications are coming from the semiconductor industry whose worldwide sales rose to $166.4bn in 2003 and are expected to reach the area of about $200bn in current 2004, as SIA says. Market watcher Isuppli, for example, saw the market in 2003 at 178.4bn, predicts 208,8bn for this year, and expects a CAGR of 11 % between 2002 to 2007. Whatever the real figures are and on which basis generated, the signals direct upwards. As we probably all know, components must first be manufactured and then finally be assembled onto PCBs, and therefore the revival must become evident in these equipment areas as well. The question is simply: when and to which degree will the scenario begin to improve? And, not to be forgotten: because of the roller-coaster ride of the dollar against the euro, the situation for European companies serving the global markets where invoices are quoted in US-dollar, is not easy. At any rate, according to a survey of the show organizer, more than 60 % of the exhibitors and visitors alike expect the market to recover soon. Tilo Keller, Ersa director of marketing, is also pleased with the show, ”We’re extremely happy with the number of visitors, and how international they are”.

For instance, Michael Brianda, general manager of DEK Central Europe, confirmed that, ”…in Europe, I’ve been seeing a positive trend for the past three or four months; by next summer the entire industry should be reaping the benefits”. Also marcom manager André Myny of Vitronics Soltec sees positive development, ”We are happy with the number of visitors; we have lots of traffic at our stand. Business is picking up, people are looking for investment.” The exhibitors in general seem to be well-prepared for this economic upturn. There were a wealth of new products, solutions and technologies circling around manufacture on display at Productronica, and visitors showed serious interest. ”Our customers have a large number of specific projects” resumed Eckhard Sperschneider, managing director of Macrotron Scientific Engineering. And Helmut Rutterschmidt, managing director at Datacon, is confident about the course of business, “We are certain that we can achieve a 20 % increase in sales. Our strong investments, especially also during the recession, will pay off in the forthcoming growth phase. Many leading and worldwide acting semiconductor manufacturers and subcontractors have fitted their pilot line for advanced packaging with our equipment”.

Productronica confirmed its business-to-business concept with 99.9 % trade visitors, and they were more international than the previous event, as Messe Munich reports. And this despite the increased cost awareness and restricted travel budgets. It was mostly decision-makers who came to the event. The quality (whatever this means in this context) of the contacts between visitors and exhibitors was correspondingly high. Most visitors already had very specific projects in mind, so that exhibitors were able to report contracts being placed at the booth. Contacts were mostly European, some Asian and some from the US. But people have a budget to stick to. The market is growing slowly, not booming, but perhaps the growth will be more stable and reliable.

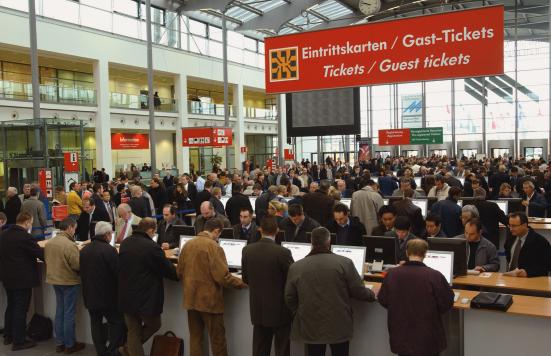

The topic of lead-free production ran like a continuous thread through the entire event. All seats at the Productronica Forum (see separate report in this issue) were taken when seven leading experts from manufacturing industry and research held a panel discussion on this demanding subject, a change in the manufacturing paradigm. Another important topic, micro-systems technology, was covered by an exhibition, a user forum and live demonstrations. The Flibusi assembly line (flip-chip die bonding for ultra-thin silicon) illustrated automated production of smart labels, and proved one of the highlights of the trade fair. Klaus Dittrich, managing director of Messe Munich, feels satisfied with the way the fair went. ”The high quality of the forums and arenas was achieved with the support of the organizations VDMA, ZVEI, and SEMI.” But he wasn’t happy with the registration of visitors. „The lines at the entrance were sometimes considerably long, and we are very sorry about delays. We’ve already taken steps to see that things will be better in future.”

West meets East or cry for a battle?

In his role as chairman of the German VDMA Productronics association, CEO Franz Richter of Suss Microtec stressed the importance of MEMS as a candidate for the future growth of the European semiconductor industries. MEMS, in their main application, IT peripherals, reached a world market volume of almost $20bn in 2000. According to Nexus market research quoted by Dr. Richter, MEMS is poised to grow strongly to $38bn in 2005. Biomedical applications, next in line, will alone consume MEMS for about $18bn in 2005, showing an even steeper increase from earlier levels. Other prospective and prosperous industry segments, such as automotive and telecom, will all expand the use of MEMS, although they will stay well below $5bn annually in 2005.

The economic outlook for, in German parlance, Productronics (meaning electronics production), Richter says, speaking for 80 special member firms within VDMA, envisions a moderate market growth of 3.6 % in 2004. Capacity utilization is currently at normal levels at more than 60 % of the VDMA member firms, carrying an average order backlog of about three months. “Five to six months would be better,” Richter beliefs. But “the upswing is visible,” despite the fact that equipment vendors still lag behind the vigorous economic acceleration of semiconductor makers. “In such times of crisis”, Dr. Richter thinks, “innovation is an important key word and motivator. But innovation needs investment too because innovation is nothing to be had at price levels as low as those of today geared to mass production and mass consumption. Innovation, in other words, is tied to high-end achievement”.

Peter Drexel, member of the board of Siemens Dematic, raised similar concerns. The electronics assembly equipment business, currently under heavy stress from sluggish to zero demand and on a painful migration to Greater China, „will grow again over the next couple of years – albeit at an average annual pace of only 6 to 8 %”. The structural changes in the customer setup – OEM, ODM and EMS – will continue, Dr. Drexel states, causing definite changes in the evolutionary direction of the assembly equipment and services business.

Careful balancing risks and rewards

“Innovations in traditional surface-mount components”, Drexel underlines, “will no longer serve as drivers of high-end machines. More and more, there are specific customer groups that need to be catered to as the variety of individual SMT processes and solutions continues to increase. The high-end section of placement machines is shrinking, while the mid-range segment is expanding. Chip assembly takes a part of high-end”. Even the battle cry “Go East” is not heeded blindly anymore by all electronics manufacturers these days. Non-satisfactory efficiency, lack of process quality and personnel qualification are significant hurdles on the long march into China, Dr. Drexel points out. Careful balancing risk and reward has to replace the prevalent euphoria.

Structural changes are in the offing for worldwide operating EMS providers too, as Sven Grimm, director of business development at Sanmina-SCI, observes. He lauded the new focus of Productronica on EMS generally and on the logistics aspect of global electronics manufacturing in particular. The EMS industry is neatly growing despite being surrounded by doom and gloom, achieving average annual growth rates of 10 %. “One reason for this”, Grimm assumes, “is that the overall outsourcing movement today has reached only 20 to 25 % of the potential. Three out of four products are still being produced in OEM-owned production sites”. Regionally, about 23 % of all EMS revenues are located in Europe (EMS still being a novelty as a manufacturing paradigm, especially for small and medium enterprises). The majority of all EMS expenses, about 46 %, are spent in the Americas (counting Mexico as the first beneficiary and recipient of the manufacturing migration out of the U.S.). East Asia, at this point, takes 31 % of all EMS revenues. But it is rapidly growing at an annual rate of 20 %. What will remain at the traditional industrial locations is small-series, high-end manufacturing, exceptional short lead-times, close contact in the same time zone and a common understanding of business procedures and ethos. Grimm beliefs that R&D is clearly the next prospective production factor to be outsourced to foreign shores.

The next Productronica will take place from November 15 to 18, 2005 at the New Munich Trade Fair Center. But before another baby, the ProductronicaChina takes place at the Shanghai New International Expo Center (SNIEC) from March 17 to 19, 2004.

(WS/gbw)

EPP EUROPE 407

Share: