Systems required to convert primary energy into electrical energy have undergone numerous paradigm shifts. The focus today lies primarily on efficient and sustainable energy supply and use, with components such as power semiconductors playing a key role.

SwissSEM Technologies specialises in the development and design of power semiconductors. Its experts are particularly concerned with voltage classes such as those used in the rapidly expanding automotive and renewable energy market segments. A dedicated R&D team develops the power semiconductor chips and packages and tests them in a specially-designed laboratory. Hilpert Electronics supports these experts by providing tailor-made quality assurance products and services for use in production.

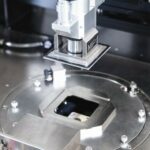

“During the development phase, rapid and efficient testing of the design of power electronic packages in accordance with strict quality specifications is of crucial importance,” explains Roger Stark, Head of Test Laboratory, SwissSEM. To do this, the manufacturer relies on the semi-automatic high power probe system TS2000-HP from MPI Advanced Semiconductor Test, delivered turnkey by Hilpert Electronic. The shielded probe system is designed for measurements of up to 10 kV 600 A and offers a wide range of functional advantages and configuration options. The developers also benefit from close collaboration with the technology supplier as well as direct contact with the prober manufacturer MPI.

Precise measurements, intuitive operation

The high-precision system can be used during prototype development to check whether a design meets the process requirements. The system is characterised by a wide range of functional features. A well-thought-out user interface guides the user through the required steps and thus minimizes incorrect operation. The operator is thus able to familiarize himself with the machine within a very short time through this ‘learning by doing’ approach. “I experienced the diverse product features of the MPI-Probers during previous employment relationships. For this reason, and because the system fits well into the requirements and cost framework, SwissSEM also chose this system,” says Stark.

Flexible design-specific wafer testing

The power semiconductors to be tested have a particular construction characterized by very fine structures. The MPI system is nonetheless able to contact the components precisely. “The prober is able to navigates from chip to chip across the entire wafer for the functionality test as part of the semi-automatic work process. The number of wafers to be tested can vary depending on the design. Process and production corrections are possible in different phases,” explains Stark. The user-friendly software program also allows corrective action to be taken at any time and can also be updated independently by the user.

Another distinctive feature is the option of placing an additional camera on the side in order to provide an additional viewing angle to the bird‘s eye view from the camera at top of the microscope. “This additional horizontal perspective has proven to be particularly advantageous when making contact with multiple needles,” emphasizes Stark.

MPI continuously develops the functionalities of its probe systems based on customer requirements, among other things. The manufacturer has designed a special interface panel for SwissSEM. As a further example, a specific Chuck-Liquid-Tray with a Teflon frame can be cited. “This special tray allows chips to be contacted directly even if they are installed in a housing. This makes design testing much easier,” says Stark.

Zusammenfassung Résumé Резюме

Ein Leistungshalbleiterhersteller setzt auf ein modernes Probersystem, welches eine breite Palette von Testmöglichkeiten für erneuerbare Energien und E-Mobility-Lösungen bietet.

Un fabricant de semiconducteurs de puissance mise sur un système d’essai moderne qui offre un large éventail de possibilités de test pour les énergies

renouvelables et les solutions d’e-mobilité.

Производитель силовых полупроводников полагается на современную испытательную систему, которая предлагает широкий спектр возможностей тестирования возобновляемых источников энергии и решений для электронной

мобильности.