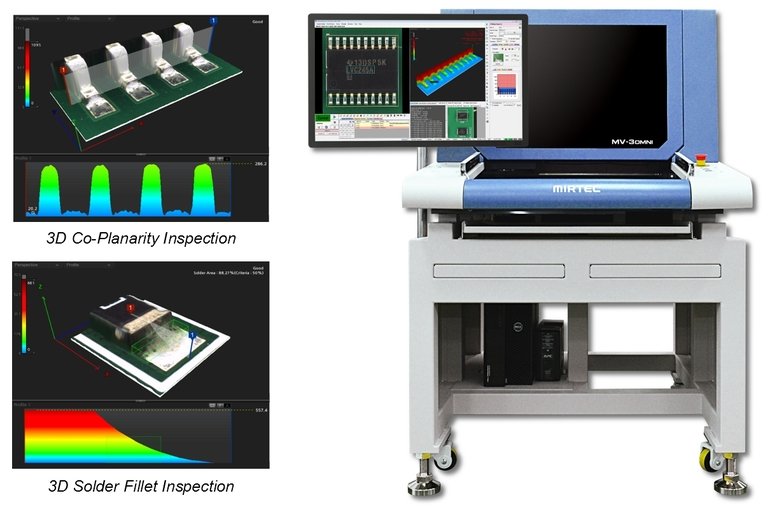

Mirtec, a supplier of 3d inspection technology, announced they will display their 3D AOI systems, MV-6 OMNI and MV-3 OMNI, as well as their total quality management system software, Intellisys, in distributor pb tec’s booth at the upcoming SMT Hybrid Packaging show, scheduled to take place June 05–07, 2018, at the Messe in Nuremberg, Germany.

The company’s MV-6E OMNI and the MV-3 OMNI are both configured with the Omni-Vision 3D inspection technology which combines 15 Megapixel ISIS vision system with the Digital Multi-Frequency eight projection 3D system to provide precision inspection of SMT devices on finished PCB assemblies. The 15 Megapixel top camera and four 18 MP side cameras guarantee a spatial check of complicated components and a secure testing of lifted leads and J-leaded components as well as text recognition on leaded devices. The 8 phase color light (RGB and yellow plus 4x white) enables a clear recognition of Lifted Leads and solder joint inspection. Beyond that, all AOI systems from the company are equipped with telecentric lens for a distortion-free image magnification.

The data transfer technology CoaXPress increases the 3D inspection speed about 40 % compared with the camera link technology. The integrated new Blue LED Moiré system enables an accurate measurement of components with reflecting surfaces. Also, with the compact design of both systems the customer saves valuable space in the production line.

In order to fulfill the requirements of Industry 4.0, customers need to have software tools to track and control their manufacturing processes. The total quality management system software, Intellisys, promotes continuous process improvement by allowing manufacturers to track and eliminate defects on inspected assemblies.

As simplified AOI programming of new PCBs becomes more important in the electronics industry, customers can benefit from the Auto Teaching Tool (ATT), which provides programming of new PCBs with just one click.

SMT Hybrid Packaging, Booth 4A-140