Electronics manufacturers are facing many challenges. The industry, especially in Europe, is focused on small to medium batch sizes, which require more frequent line changes. This can negatively affect productivity and can lead to excess wastage. New technologies, including flexible boards and smaller components, also make line changes even more difficult and demanding.

To stay productive and profitable, while increasing efficiency, equipment needs to be flexible enough to cope with a wide variety of product variations, and still be able to changeover to different designs quickly and easily without disturbing the workflow of the plant. To cope with these changing demands, manufacturers may turn to a single machine that can perform several tasks, instead of having several dedicated pieces of equipment.

In this article, we talk to Paolo Bertoldo, Automotive Business Development Dep. of Seica, to understand how the company’s Compact line of in-circuit and functional testers help manufacturers to meet the needs of today’s manufacturing industry.

How are manufacturers incorporating the Lean philosophy?

Manufacturers often follow guidelines to enable them to implement the latest techniques and meet global standards. The World Class Manufacturing (WCM) guideline was created with the intention of defining manufacturing practices according to standards recognized worldwide. The basic tenet of the guideline is the systematic reduction of all types of waste and loss through the use of rigorous methods and standards, with the involvement of everyone in the organization.

How does the Compact range help manufacturers?

Firstly, I think it is important to stress the need for flexibility in manufacturing. The Compact series has been designed for maximum configurability, to enable the series to meet today’s diverse test requirements. This flexibility defined by the VIP platform allows the user to choose the configuration which best suits the application: in-circuit tester, in-circuit programmer, functional test bench, or a completely automated test solution to provide a powerful tool that is not confined to one specific function.

The configurability of the range is supported by the single Seica proprietary VIVA software environment, meaning that all of the test functions mentioned above can be implemented easily. The single environment means that technicians only need to learn one set of tools, saving training time and costs. It has integrated tools to deal with test program generation, debug, execution, diagnostics, repair and data logging.

The Functional Graphic Environment guides the user through a series of automated operations in an intuitive environment. A series of complete test libraries for both analog and digital components is available in the dedicated test language.

VIVA is also compatible with numerous other “front-end” packages and allows easy integration of external software modules, as well as third party languages and sequencers such as Labview and Test-Stand.

How is the system manufactured to be so flexible?

At the core of all Compact systems is the ACL Synthetic Instrument, which uses independent D/A and A/D converters for each synthesized instrument. Each card hosts three independent Arbitrary Waveform Generators, a Multimeter, a Timer-Counter, and large on-board memory and processing capability to enable signal analysis and digital scope functionalities. Four high speed digital channels are also available and routed, like other signals, through the analog signal bus, or can be directly accessible on the front panel.

Controlled by the system PC through the high-speed fiber-optic bus, the resources present in the card reach the device under test by using digital and analog cards, which are then available on the system receiver for any type of use.

Does the company’s platform support the latest test requirement?

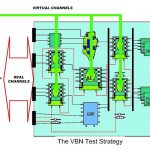

I can start with an example: if Boundary Scan testing is required, the company’s Virtual Bed of Nails (VBN) capability can increase test coverage using the JTAG pins on the UUT as a group of I/O virtual channels, adding driving and sense capability, even though direct access is not available for that group of pins. The VBN module does not require additional hardware resources.

Besides that, a fully-integrated On-Board Programming (OBP) solution can be included in any Compact series system. This solution offers important advantages in terms of operational costs, speed and ease of use, ensured by the dedicated SW management environment. The maximum configuration is up to 16 devices that can be programmed simultaneously, which includes an available library of dozens of available plug-ins.

Moving on to software features, can we discuss the repair station or statistics modules?

The repair station module provides a graphic software environment for fault location and repair. After the test phase, the operator can recall and visualize the faults detected on every tested board and the relative circuit connections of the implicated components. A dialogue displays all the critical points requiring inspection, and allows the operator to enter the information regarding the repair actions performed, which are then stored in a database.

The QSTAT tool uses this database to generate troubleshooting tips and repair information for the operator, and can create reports related to repair activity on boards tested. To facilitate the collection and analysis of data, the database can collect repair actions on multi-panel boards, on board panels, and single boards. The SPC tool enables the statistical analysis of test data, and the generation of CP, CPK, and Gauge R&R reports.

What if I need to perform functions that are not supported by the base tester?

The open architecture of the VIP platform enables the easy integration of external software and hardware modules, managing not only test, but also with programing capabilities. For example, additional modules are available for high voltage analysis or RF testing.

Apart from the test process, how does the Compact range facilitate Lean manufacturing practices?

The WCM guidelines go much further than manufacturing, defining manufacturing practices in general. For instance, the Compact line machines are designed to comply with the ergonomics, servicing, and safety features described by the guidelines. This makes the range easy to use and safe for the operator, while being easily accessible for servicing. All gauges and indicators are positioned for easy monitoring, and the machines are designed to reduce or eliminate downtime.

productronica, Booth A1.445