Wacker Elastosil N9111 from Intertronics is a tin-free single part RTV silicone adhesive sealant, with a neutral cure chemistry, producing a non-corrosive seal that does not inhibit other materials such as platinum cure silicones. This, along with its UL94 V-0 rating, makes it a strong candidate for electronics manufacturing, especially for gap filling, component ruggedisation, and form-in-place gasketing.

This sealant is also well-suited for automotive and small appliance electronics and for new/sustainable energy devices and similar. Further applications for this general-purpose adhesive sealant include demanding bonding applications in the household appliances sector, e.g. bonding of ceramic hobs, screens and control panels in electric cookers, or mounting and bonding of front windows of microwave ovens. It is technically an alkoxy-curing RTV-1 system, formulated with a tin-free catalyst. It is therefore ideal for applications in which organo-tin compounds act as inhibitors and are therefore undesirable, such as dam-and-fill applications.

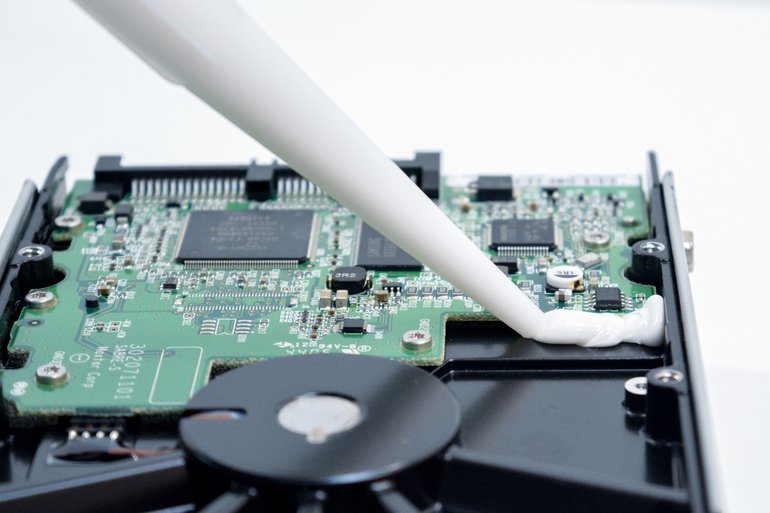

For instance, the silicone adhesive sealant makes encapsulation of electronic modules significantly quicker and easier in situations such as dam-and-fill. In this process, a bead of non-sag silicone is applied to the module to create a dam around the encapsulation area, which is then filled with a low viscosity encapsulant such as a platinum-catalysed silicone gel. This avoids the situation which occurs if the RTV-1 silicone used for the bead contains a tin catalyst, in which case the silicone must be fully cured before encapsulation – otherwise the tin will inhibit the curing of the platinum-catalysed encapsulant. As a result, using tin-based RTV-1 silicones for such procedures is always time consuming and cost intensive. Elastosil N9111 has none of these drawbacks and consequently promotes productivity and process simplicity.

Physically, it is a soft, non-sag paste. Its viscosity decreases when shear is applied. This „shear-thinning“ enables the silicone rubber compound to be readily applied both manually and mechanically. The material is available in black and white and adheres to many conventional substrates, such as aluminium, stainless steel, glass, polyamide and polyvinyl butyral. The cured rubber is resistant to both UV light and temperatures of up to 200 °C.