Under the slogan ‘Your Partner for a Smart Factory Realization’, Koh Young Technology demonstrated how its true 3D solutions can improve production throughput and yield at productronica. The company featured a broad display of innovative solutions powered by its Intelligent Platform that included a 3D Solder Paste Inspection (SPI) system, a full 3D Automated Optical Inspection (AOI) solution, and several new platforms.

AOI systems

The company unveiled its 3D AOI platform that includes technologies like Auto Programming that reduces job preparation by up to 70 %. This latest platform incorporates additional innovations, for example, side view cameras to expand height measurement and to further enhance defect identification capabilities.

SPI systems

3D SPI systems were also on display, including the KY8030–3. New features like Auto Repair eliminate rework and scrap while improving ROI by automatically dispensing solder paste on failed pads without stopping production. The aSPIre 3 was also on display, which has an automatic measurement verification to ensure the best inspection results.

New systems

Leveraging its core strengths in robotics and 3D measurement, the company brought the next generation of accuracy to the pin inspection and machining inspection markets. The KY-P3 pin inspection solution can measure both height and offset for single pins. The Infy offers precise full 3D optical inspection solutions for machined products like mobile phone cases.

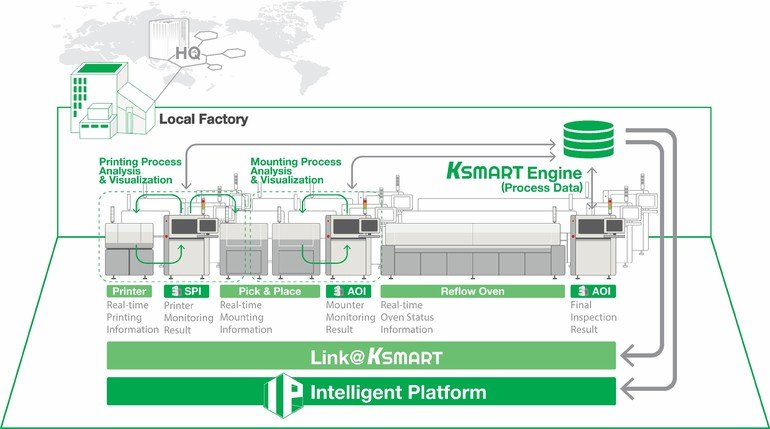

Industry 4.0 solutions

Beyond the comprehensive KSMART smart factory solution, featuring an improved user interface, the company harnessed true connectivity by demonstrating its closed-loop process optimization software, the KSMART Process Optimizer (KPO). This was shown in conjunction with the company’s printer and mounter partners. For example, Fuji Europe also demonstrated this software in-line. It includes three complementary modules, which actively optimizes the print process to reduce false calls and improve yield performance. The company has also been working with MPM, EKRA, and others to develop the required network infrastructure for the software