Visitors to Productronica in Munich who come and see Seho can look forward to a variety of soldering highlights and a PLUS of innovations and services. The focus is on increased efficiency and productivity in electronics manufacturing.

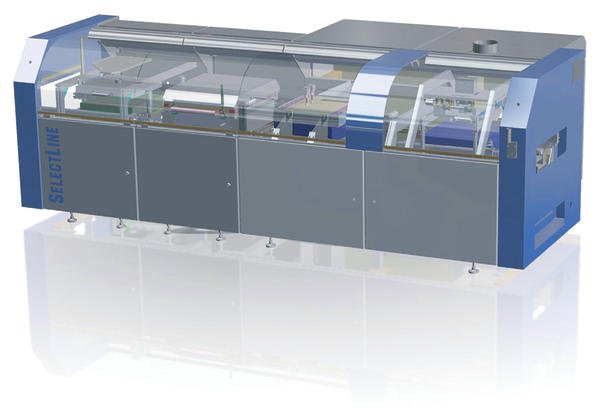

Time plays a key role in modern electronic production. At Productronica 2013 Seho introduces their new product family SelectLine, a fully modular selective soldering system. Its revolutionary design convinces with high precision and a high degree of flexibility – no change-over is required to dynamically process a variety of assemblies with short cycle times. In the fluxing area the new creative axis fluxer offers extra versatility. Multiple axes are used for parallel, even asymmetrical, fluxing to help reduce cycle times. Its high-precision micro-drop nozzles can be programmed completely independently. And of course, different fluxes can be made available permanently to cover various process requirements without set-up times. SelectLine preheating types and length can be configured individually. The soldering area – heart of SelectLine – also scores highly thanks to its outstanding flexibility. Several solder pots with different solder nozzles, either completely wetted or a directed solder flow to one side, can be integrated. They work in parallel and ensure maximum throughput. For small lot sizes and high mix of assemblies different alloys can be processed without additional setup effort. A unique feature is the possibility to integrate an AOI system for solder joint inspections directly into the system – a big plus with regard to space and handling costs. The solution, of course, offers a complete hardware and software package for automatic process control. It monitors flux amounts, including the actually applied amount, provides automatic position correction and z-height correction, controls the wave height and ensures MES integration. It is available both as a individually configurable modular inline solution and as a compact stand-alone model.

Specific applications, such as wave soldering with masks, require selective flux applications that wet only the points to be soldered, not the entire mask. This prevents flux from running under the mask. It also significantly reduces flux consumption and shortens the cleaning cycles for the masks. The company has developed the coordinate fluxer SelectFlux for this purpose – a high speed system which precisely applies the flux at previously programmed points. No other assembly areas are wetted. The company will will also exhibit the PowerWave N2 nitrogen system for wave soldering. This solution has been specially developed for medium to large series production and is designed primarily to optimize product quality and minimize production costs. With its relatively low investment costs and low consumption values, the unit offers an optimum price/performance ratio, ensuring high profitability. This is realized through its innovative tunnel concept, individual speed control for transport segments, a modular preheating concept and the advanced soldering area that facilitates sector-based soldering.

The new PowerReflow-2 completes the product range for reflow solutions. With a heating zone length of 2700mm, it was specially designed for medium to high production volumes. Nine heating zones and an active 900mm cooling area provide flexible temperature profile settings and perfect solder results. The integrated process gas cleaning system ensures low maintenance. Thanks to its modern control system, easy-to-program software, interfaces for integration into a fully automated production line and many additional features, the system offers exquisite soldering technology and an ideal price/performance ratio.

The PowerSelective soldering system convinces with high-precision solder results and a flexible process for miniwave and dip applications. Depending on the production requirements the system can either be integrated into a fully automated manufacturing line or in a lean production concept with creative handling solutions. Ergonomically designed work places with individual height adjustment for loading and unloading, inspection places, or assembly areas for additional processing of assemblies flexibly enhance the soldering system. The many features for automatic process control include the ability to integrate an AOI system for solder joint inspections directly into the process.

SEHO also launches ViproInline, an AOI module that can be integrated flexibly into a fully automated production line after the wave or selective soldering process to check assemblies for common THT solder faults as well as missing and misplaced components. Under reproducible test conditions this helps to make early trend statements about the production process. The obtained data contribute significantly to process optimization and help to increase production quality.

The MaxiReflow HP breaks new ground. This solution provides the ideal combination of convection heat and a special pressure module to obtain nearly void-free solder joints. It is equipped with an innovative peak area pressure chamber which enables convection to be used for heating of assemblies and features a nitrogen atmosphere to avoid oxidation. With non-critical assemblies, it can also be operated without activating the pressure chamber; boards then undergo a conventional reflow process. Since the pressure chamber is integrated into the peak area, no additional space is required. In comparison with existing technologies for the reduction of voids, the system offers several key advantages. High pressure soldering eliminates impurities around solder joints, in particular solder balls, and it can handle even critical components, such as electrolytic capacitors. The company also introduces its new online service portal, where customers have easy access to all the data for their systems, including user manuals, circuit diagrams and logs. With just a few clicks users can identify spare parts and send an automatic request to the company. This is just another benefit of the “More for You” the service initiative which provides customers with a comprehensive package of services. Customers can select their own components that will benefit their individual manufacturing processes and increase profitability. They can choose from many different elements, such as staff training at SEHO Academy, machine capability studies, RoHS measurements and customized maintenance contracts.

Productronica, booth A4.578

Share: