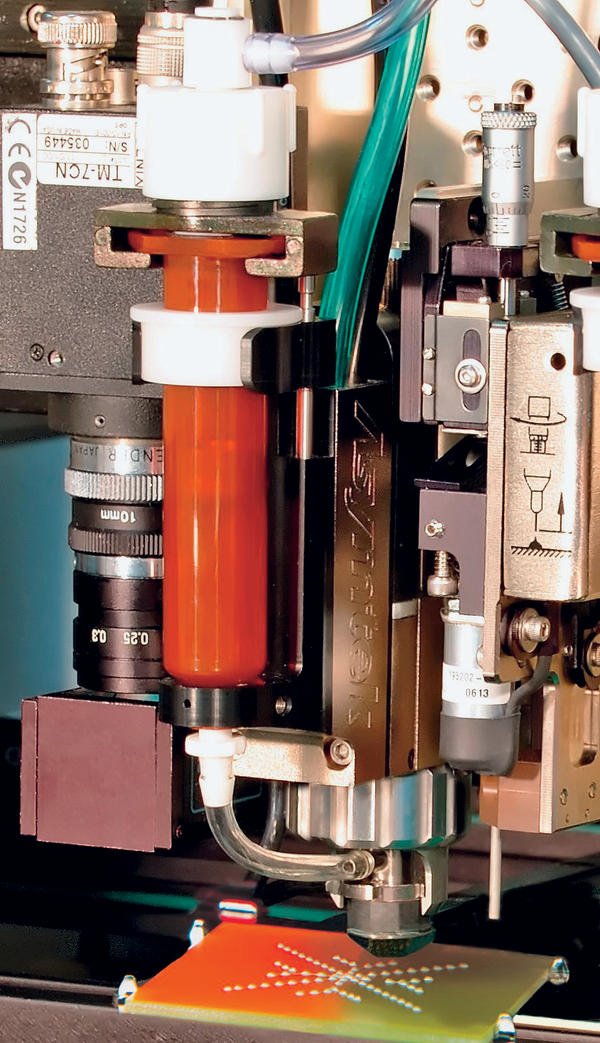

Asymtek has introduced two coating/dispensing technologies for applying catalyst inks onto membranes in electrode assemblies of proton exchange and direct methanol fuel cells. Pulse spray coating technology provides quick large area coverage, allowing for uniform film thicknesses. Dispense-Jet technology deposits the ink with a uniform thickness and density so lines and patterns are smooth, even, and the same consistency throughout. The consistent and precision application of the ink increases the porosity of the film so fuel and byproducts can pass through the membrane efficiently.

The company offers fuel cell manufacturers two types of application technologies for increased dispensing flexibility: Spray coating and discrete dot dispensing. Spray coating is for large areas, for controlled thicknesses, and even film thicknesses. Discrete dot dispensing is used for specific patterns with high edge definition and exact film build up of highly volatile inks. The enterprise has a multiple array of coating and dispensing technologies for catalyst inks, polymer electrolytes, gasketing, and sealing depending on the application.

Catalyst inks are very expensive because of the platinum content. With the jet, the ink is deposited precisely where it is programmed to be placed, so there is limited waste. The jet deposits discrete dots in whatever pattern is desired without masking. The closed-loop system measures the exact amount of fluid that’s deposited. Process controls and the firm’s Easy Coat for Windows XP (ECXP) software regulate the volume, size, shape, and viscosity of the dot. Selective spray coating is a highly selective method of jetting materials and enables fluid to reach locations not possible with other applicators. Dot sizes to 1.2 mm (0.05 in.) are possible as well as thinner film builds of 5 µm. Jetting is fast, up to 500 mm/sec (20 in/sec), because there is no Z-axis motion. The system is so accurate that it eliminates the need for masking. The system is easy to disassemble and maintain.

EPP Europe 546

Share: