Saki Corporation, an innovator in the field of automated optical and X-ray inspection equipment, has released a job data convert function that enables the automatic generation of data for board inspection on the company’s 3D AOI systems by using the component information data generated for pick & place machines. This new conversion functionality enables users of Saki’s 3D AOI systems to significantly reduce the time taken to create board inspection programs by directly importing the pick & place data to automatically generate a library for PCBA inspection.

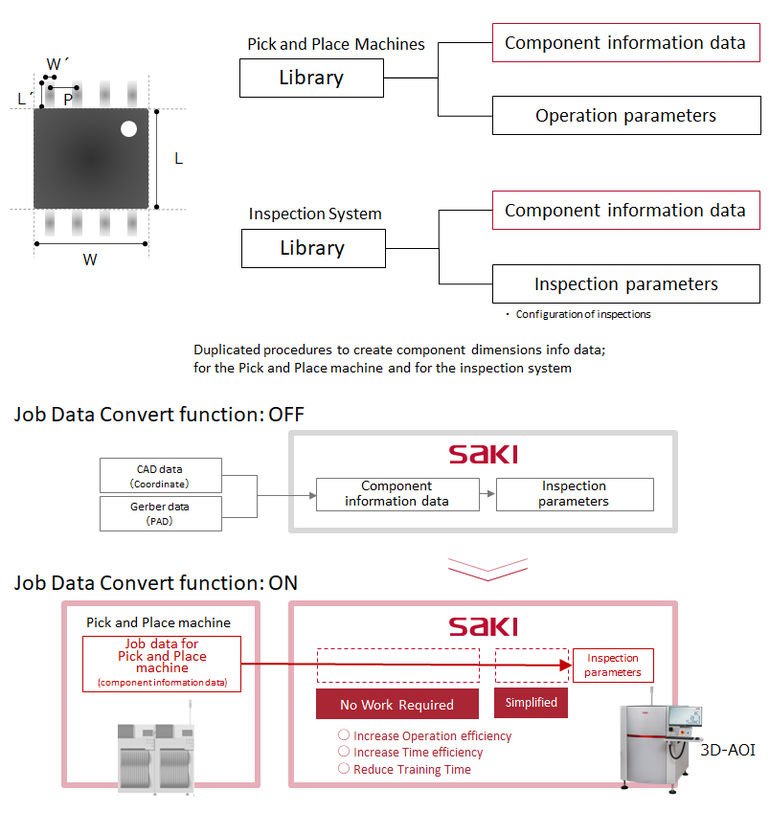

In a typical surface mount assembly process, the production engineer sets up a data library for the placement machine, which includes the physical dimensions of the components to be placed. It is also necessary to build up an inspection data library that contains the same component information to create a program for the board inspection system, which sits downstream from the pick & place machine. In typical SMT assembly lines with pick & place machines and board inspection systems, users must duplicate effort to create data libraries of components for both machines separately, which presents a productivity challenge for assembly line operations.

To address this, the company has collaborated with pick & place equipment manufacturers to develop the job data convert and automatic library generation function. The new function works with all of the company’s 3D AOI machines. Not only can users save time while creating inspection programs by introducing this function to their inspection systems, but they can also use it to simplify programing procedures and the training for the programing.

As of February 2021, the first supplier of premium pick & place brands covered is the connected solutions company, Panasonic Corporation. Further collaborations with SMT assembly system partners will follow.

Yoshihiro Akiyama, Director and CTO, said: “As well as seeking to improve the quality and inspection accuracy of individual inspection systems, Saki offers a wide range of solutions that contribute to improving the quality and productivity of the entire production line, helping customers to realize a Smart Factory. The newly developed job data convert function can be added as an optional feature to all Saki 3D AOI systems. We will continue to expand our collaborations with SMT assembly system partners to deliver convenient, effective, and intuitive data coordination solutions to our customers that help to increase the productivity of their SMT lines. I invite you to visit our online demonstration to see the innovations behind our next-generation automated inspection solutions for the high-quality Smart Factory.”

SAKI Corporation

DMG Mori Tokyo Innovation Center

3–1–4, Edagawa, Koto-ku, Tokyo 135–0051 Japan

Tel.: +81 3 6632 7195

E-Mail: info@sakiglobal.com

Website: www.sakicorp.com