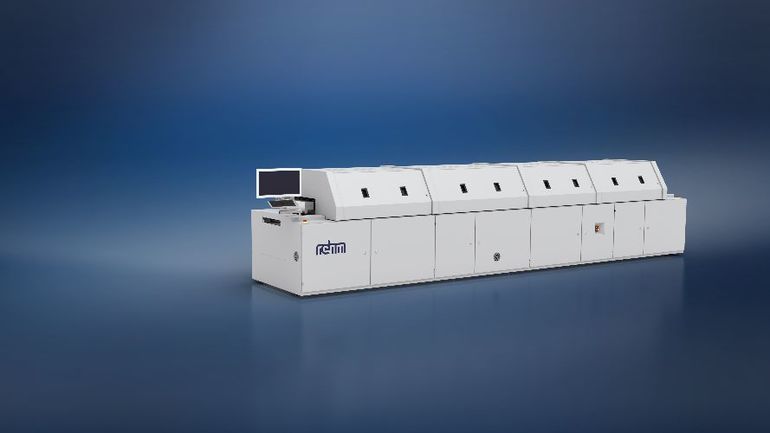

With VisionX Semico, Rehm Thermal Systems developed a system that was adapted to the special requirements of the semiconductor market segment. It is based on the proven Vision series, which has been successfully established in the reflow soldering market for years. Especially important for the development of the VisionX Semico was the compliance with all specifications for the use of the system under clean room conditions. The VisionX Semico is certified for clean room class 1000 and designed for high throughput. Optimal heat transfer through specially developed nozzle arrays ensures a small delta T and thus the best process performance.

The low-vibration transport, whether designed as braided tape, pin chain or combined transport, and as single lane or dual lane, meets the high demands of semiconductor production and ensures additional process reliability. A particular advantage of the system is the flexible configuration of the cooling line. Here, the components in the respective zones can be supplied with either cold air or warm air. A combination of cold air above, warm air below or vice versa is also possible. This enables gentle, stress-free cooling of components and guarantees flexible outlet temperatures.

The development of the VisionX Semico naturally also focused on energy efficiency and ease of maintenance. The system is equipped with particularly high-quality insulation which meets the requirements of the cleanroom class and ensures maximum energy efficiency within the process chamber. Pyrolysis is integrated as standard for reliable cleaning of the process air. This pyrolysis ensures a dry and clean process chamber and compliance with the exhaust air specifications for cleanroom concepts and requires maintenance only once a year. In addition, a condensate trap is installed as standard in the cooling track, which reliably separates the crystalline residues and ensures simple maintenance and extended maintenance cycles. The technical design of the system, paired with innovative, modern software, is decisive in ensuring that the VisionX Semico is optimally equipped for all current and future SECS / GEM / Industry 4.0 / MES solutions.

With the VisionX Semico, Rehm has developed a system that is optimally designed for the production of components under cleanroom conditions and has once again shown that all areas of thermal systems are well within the company’s territory.

Rehm Thermal Systems GmbH

Leinenstraße 7

89143 Blaubeuren-Seissen

Tel.: +49 7344 9606–0

E-Mail: info@rehm-group.com

Website: www.rehm-group.com