Pickering Interfaces, a leading supplier of modular signal switching and simulation solutions for use in electronic test and verification, has launched a new family of battery simulator modules which it says are ideal for Electric Vehicle (EV) battery stack emulation in Battery Management Systems (BMS) test applications. The 41–752A (PXI) and 43–752A (PXIe) modules enable direct voltage and current readback either programmatically or using its soft panel control. Each cell simulator is highly accurate, specified at ±5 mV from 1 V to 7 V.

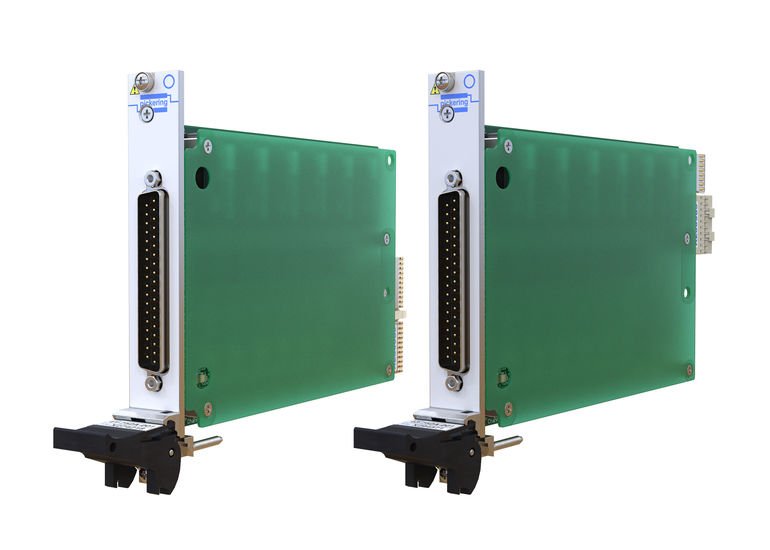

Targeting EV, automotive, aerospace, energy storage and electric aircraft applications, the new battery simulator modules occupy a single PXI slot. They are available with two, four or six battery cell simulators per module that are fully isolated from ground and from each other facilitating series connection to simulate batteries in a stacked architecture. The 750 V isolation barrier allows the modules to be used to simulate lower power battery stacks that are commonly used for vehicle propulsion. Battery charging emulation is available up to 100 mA.

Each cell provides independent power and sense connections, allowing the simulator to sense a remote load and correct for wiring losses. The battery simulator is designed to respond to dynamic loads, minimizing the need for local decoupling capacitors at the load. The module can also independently read the voltage at the load (via sense lines) and output current for each cell. When supplied with I/V readback, the driver can automatically adjust the module‘s output voltage through a feedback system, allowing higher accuracy.

“With the increasing adoption of EVs as well as battery stacks for other applications, one of the significant challenges to be tackled is the effective testing and validation of the Battery Management Systems (BMS),” commented the company’s Simulation Product Manager, Paul Bovingdon. “Previously, test engineers have had to link simulation modules to a separate DMM to achieve voltage and current readback. Our new modules eliminate this requirement, making them simpler to use and more accurate. The 41–752A and 43–752A modules benefit from the modularity and scalability of the PXI/PXIe platform. These modules can be combined with Pickering‘s other PXI switch and simulation modules, including high voltage switching, fault insertion, thermocouple simulation, RTD simulation and more. They can also be combined with other vendors‘ PXI modules, such as a CANbus interface, to create a fully flexible BMS test system.”