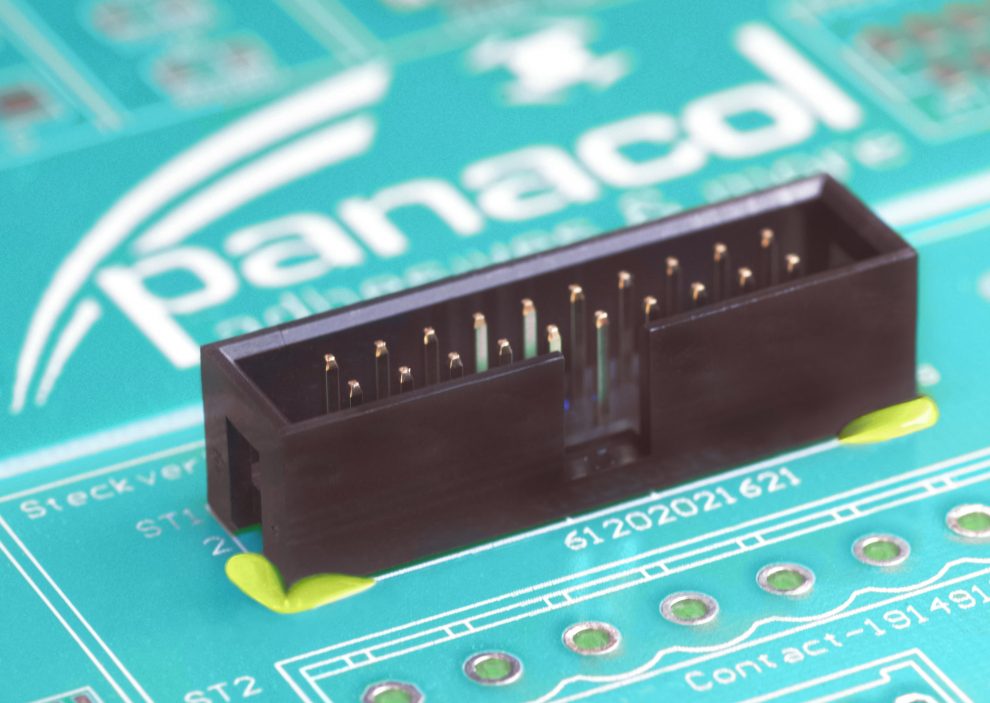

Provider of adhesives, coatings, and UV/LED curing equipment Panacol has developed a new, removable edge bonder specifically formulated for bonding consumer electronics components, known as Structalit 5705. In addition to reworkability, the main feature of the black adhesive is that it fluoresces yellow when excited by UV light. This significantly enhances the accuracy of in-line optical inspection systems, the company explained.

Edge bonding adhesives are used to quickly secure electronic components to printed circuit boards. This fastening method offers superior protection from shock, vibration, and thermal stress. As a constructive alternative to underfill processes, edge bonding increases the impact and bending strength of BGAs and other chip packages. Edge bonding can also be preferable to underfills when flux residues are present on PCB and component surfaces.

Structalit 5705 is a black, thermosetting epoxy resin adhesive that is characterized by its viscous flow properties and high thixotropy index. These properties enable precise placement of the adhesive with no subsequent migration. It may be dispensed using pneumatic valves, or through highly efficient, contactless jet dispense systems. This epoxy resin-based edge bonder is low in halogens, and is ideal for electronic components assembly.

A typical feature of PCB adhesives is a black coloring that is used for light blocking and concealment. Visual inspection of edge bond placement is commonly performed by manufacturers using in-line camera systems. Dark-colored, low contrast chips often present difficulties for precise optical measurement. The adhesive provider says it solves this problem by incorporating a yellow fluorescence into the black resin. The fluorescence is excited by short wavelength light, for instance 365nm. The highly contrasting fluorescence makes it easier for manufacturers to perform in-line inspections, resulting in faster parts processing and increased throughput.

For manufacturers of electronic components, a new challenge is becoming increasingly important. Global environmental associations are successfully lobbying for legislation to minimize electronic waste. A critical step in this sustainable strategy is the ability to rework and repair individual modules on printed circuit boards. Reworkability and repair reduces the amount of electronic component scrap that must be disposed into the environment. The new resin provides a reworkability feature. The adhesive can be removed without damaging the bonded components. This enables faulty components to be removed, and repaired after assembly.

The new edge bonding adhesive is selectively reworkable when the cured adhesive receives thermal exposure above its glass transition temperature (Tg) of 150°C. The adhesive softens, and can be manually scraped away using a small spatula or similar instrument. It is only above this critical temperature threshold that the product becomes workable. Below this temperature, the product protects bonded components with reliable bond strength and consistent performance.

Another pressing need for the reworkability of bonded components stems from the current global supply chain parts shortages. Automotive and consumer electronics sectors are experiencing massive production delays, primarily from a shortage of integrated circuits (chips) and electronic board components. The ability to rework components can help to mitigate some of these shortages. Reusing components not only offers advantages for the environment, but has also become essential for maintaining current production processes caused by supply chain bottlenecks.

Structalit 5705 edge bonding adhesive can be used in conjunction with Panacol’s reworkable underfill, Structalit 5751. Both adhesives can be applied wet-on-wet and cured together in just one oven process step. The reworkability of both adhesives provides manufacturers with the means to repair components after assembly, and reduce electronic waste.