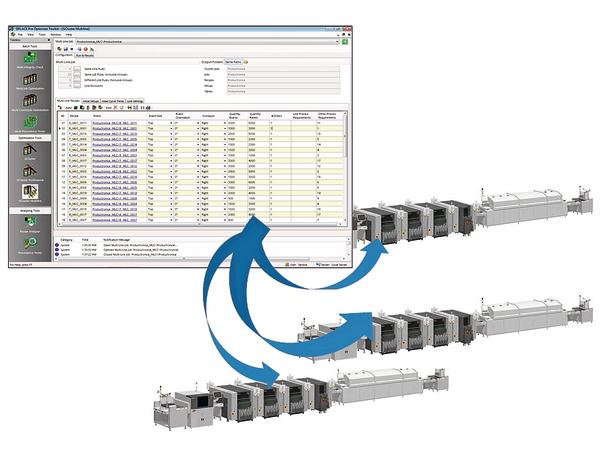

SMT production schedulers looking for ways to become more effective in their jobs are well-advised to refer to the Siplace team. New functionalities in Siplace Pro and innovations like SiCluster MultiLine and the Material Manager are valuable additions to the software suite. Combined in line with user’s requirements, these modules deliver consistent, software-supported workflows for SMT-specific planning processes, making it possible to schedule production jobs more quickly and effectively. They also improve the quality of the schedule: production capacities are used more efficiently, the number of material-related line stops drops, and setup changeover times are minimized. The new software solutions help the scheduler to group in so-called job clusters and minimize setup times. The Material Manager provides electronics manufacturers with an SMT-specific material logistics system as a transparent addition to their ERP systems. It keeps track of materials and manages iton the individual package level, and not as a single total number like most popular ERP systems. The Material Manager closes the gap between the ERP, planning and shop floor levels by controlling automatic storage systems, generating optimized pick lists, keeping track of MSD exposure times and taking into account real material consumption data reported by the placement machines. Once production jobs have been released, it is the planner’s job to place them on a detailed production schedule. To minimize the setup effort, it makes sense to combine various products and jobs into setup families. SiCluster MultiLine enables the planner for the first time to optimally schedule production jobs across multiple lines. The program takes line-related restrictions and configurations into account. It also considers correlations between products, for example for two-sided placements, submodules or products that should not be handled side-by-side. The system spreads the products across the lines and placement platforms and groups them into setup families (or “clusters”). The scheduler can even select with a simple mouse click whether he is more interested in maximizing the output or minimizing the setup effort. To further minimize the setup effort, the production scheduler has the innovative setup concepts at his disposal. For example, if components are used in various upcoming family setups, they can be grouped on specific changeover tables, which are referred to as constant tables. Since these tables stay in place when the setup changes, this concept reduces changeover times as well as the number of tables needed. Another variant that is recommended for floating setup changeovers is the Split Table Mode, which involves virtually splitting the changeover tables on the line. While one product or cluster continues to run on the line, operators can install the feeders for upcoming products in available slots. This enables the machines to keep running non-stop when the next product enters the line.

SMT Hybrid Packaging

Booth 7-204

Share: