Manufacturer of dosing and filling systems ViscoTec has brought out cartridge applicator units designed for exact and clean feeding of adhesives, pastes and silicones of different viscosities. The company says the new units are available for the assembly line as a ready-to-install module, and are supported by a pneumatic control module supplied by Festo.

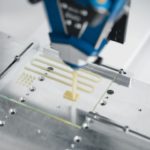

“The latest devices for automated, even application of double-chamber cartridges are called eco-FEED and vipro-FEED DC,” the company explained. “Double-chamber cartridges have the advantage of making it possible to work with media like adhesives, pastes or silicones with two components of different viscosities. Many adhesive processes depend on these adhesive components being mixed in a precise ratio. The two applicator cylinders are moved independently of each other in this process, and the correct adhesive mixture is applied to the components to be glued using a 2C mixing head from ViscoTec.”

Cooperation with adhesive manufacturers

“The right mixing ratios are the result of countless test series based on decades of experience,” emphasises Martin Stadler, Managing Director of ViscoTec. To achieve this, the product developers at ViscoTec are in constant communication with adhesive manufacturers. “Even before they launch new adhesives, manufacturers approach us to conduct initial tests with our dispensing systems,” he adds.

The cartridge emptying system and the dosing unit are fully compatible, the company says. It also points out that it is able to advise on the correct use of devices and adhesives or pastes and silicones.

“We offer our customers a service where we conduct tests for their applications in the ViscoTec labs in order to work out the correct mixing ratio and the adhesive quantities to be used at different adhesive viscosities,” said Stadler.

Precise adhesive application

In the electronics industry, minute quantities need to be applied precisely and reproducibly to circuit boards and gaps need to be precisely filled on different electronic components, often using highly abrasive pastes. “That needs a lot of experience,” explained Stadler.

This makes correct control and indication of the delivery pressure crucial. “In our devices, we rely on a control module with pneumatic automation technology from Festo,” says Stadler. It both indicates and controls the delivery pressure. It was developed in close cooperation with Festo, from the development of the prototype to the current production-ready device.

Ready-to-install control module

“The control module is a ready-to-install device supplied by Festo directly to the ViscoTec assembly line for cartridge applicator devices. It monitors the pressure and quality of the adhesive application independently of temperature and viscosity, and even enables volumetric filling, one of our specialities,” explains Christian Heidinger, Head of Product Management at ViscoTec. “It offers optical filling level monitoring as standard, although an electric version is available as an option.

“The module consists of a sturdy pneumatic valve VUWS, hand lever valves VHER, flanged pressure gauges, pressure regulators LR-D, fittings, silencers and PUN tubing.” According to Heidinger: “Having the module delivered ready for installation by Festo saves us time and effort, since we know we can integrate it directly into the cartridge applicator device without any adjustment, and can rely on the renowned Festo quality as well as the worldwide availability of spare parts.”

Countless applications

As well as precise gluing applications, the company says its dosing pumps are used in the global industry for various application such as filling cans and tubes for mascara, exfoliators or skin creams as well as for dispensing and filling fruit into jam jars, without clogging them up. “Striving for maximum precision when working with viscous media is what we do every day, and it’s why we’re the leader on the world markets,” concluded Stadler.