Monitoring machine availability while keeping an eye on material flows and ensuring that product stations are supplied with material at the right time – these are the challenges that production managers face on a daily basis. ASYS now provides an end-to-end solution for material logistics that networks all of these elements and automate the supply of materials.

The company has made a name for itself in the automation of production lines. “It was a logical step for us to look at the processes away from the line to implement the necessary automation measures there as well. We have focused on the material flows in production, which have to run smoothly at all times to meet production targets,” explains Florian Ritter, Unit Director Software Solutions & New Business. The overall goal of material logistics is to automate all material flows within production.

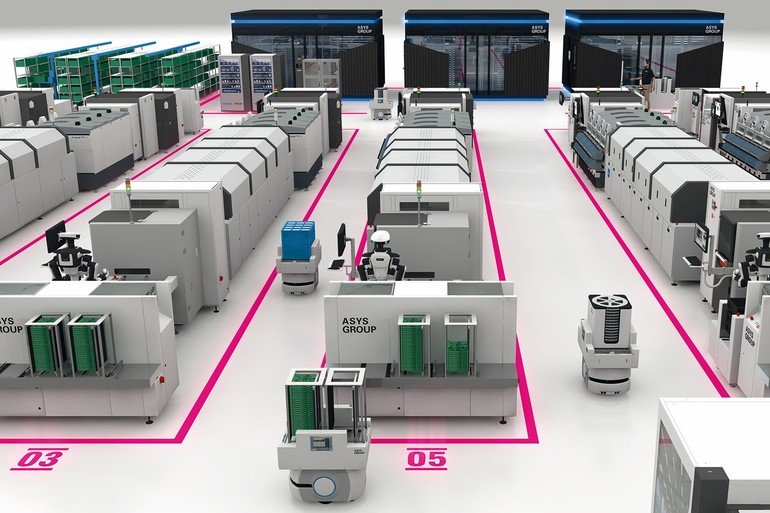

That means all types of production materials should be transported autonomously, from trays, magazines, raw materials and component reels to other process materials, such as soldering pastes, adhesives and cleaning rollers. Essential support is provided by AIVs (autonomous intelligent vehicles) which transport materials autonomously from A to B. These smart production transport systems are self-organizing. Fleet management is designed so that each robot is assigned a task that it can complete most quickly and effectively. As smart systems, they automatically detect and avoid obstacles, navigating the shortest path to their next point of work.

But the company does not just supply autonomous robots for material logistics – it provides an end-to-end solution that includes machinery, AIVs and software and networks all elements for maximum profitability. “We are seeing a trend for processes within a line to be separated from each other. This is partly due to the different cycle times. Separating the production line into standalone production centers creates new transport routes for materials. This is where we bring in material logistics,” says Ritter. Higher-level software provides a virtual map of the production line, even where processes are physically separated. This is all done by the company’s Material Manager (AMM). It collects information from all systems and uses the data to make the right decisions, such as when the robot has to set off to deliver the material to the production station on time. Current machine states are also monitored: Can the system accept material right now? Or when does it need new material? This is all mapped by the ASYS Material Manager, which independently coordinates production. “We are ahead of the game with this approach. We offer such a comprehensive solution from a single source. Our proximity to customers means that we have been able to develop this practical solution and we will now be continuously developing it. We have already completed our first projects with customers,” explains Ritter. More projects are scheduled to be completed in the course of the year.

To establish autonomous production in the long term, there are often extensive requirements to be met, which take time. However, production tasks can initially be semi-automated. “In the next step, it is then very easy to ramp up to the fully automated solution. This means that we can walk in step with our customers on the long road to the smart factory and deliver the right degree of automation for each implementation phase,” Ritter sums up.