Sabic Innovative Plastics today launched a new, breakthrough Lexan polycarbonate (PC) film technology – Lexan EFR film – that delivers non-brominated, non-chlorinated flame retardance (FR) at thinner gauges than flame-retardant polypropylene (FRPP). This new industry-leading material enables electrical/electronics OEMs to create flatter, lighter-weight notebook computers and other electronic devices while significantly reducing material costs, giving them a competitive advantage. The new Lexan EFR film is a top-choice environmental solution that increases the ability of global manufacturers to go beyond current environmental directives by voluntarily eliminating halogenated additives in their products. “New Lexan EFR film is another major proof point of how Sabic Innovative Plastics’ continued investment in R&D is raising the bar on materials performance and system cost reduction,” said Lennard Markestein, global marketing director for Specialty Film & Sheet. “As OEMs step up to meet anticipated and ever-tightening environmental requirements, we are taking the initiative in engineering precisely targeted materials technologies to help proactively address these changes.” Compared to FRPP, Lexan EFR film reduces shrinkage by a factor of three, provides significantly higher puncture resistance and tensile strength. These properties make it feasible to use very thin gauges of Lexan EFR film to replace thicker FRPP film without sacrificing performance. Not only do thinner gauges help designers create slimmer and lighter-weight consumer electronics, but down-gauging also lowers total costs by reducing the amount of material required. The new film also provides low moisture absorption, high thermal performance (glass transition temperature of 170º C) and excellent dielectric strength.

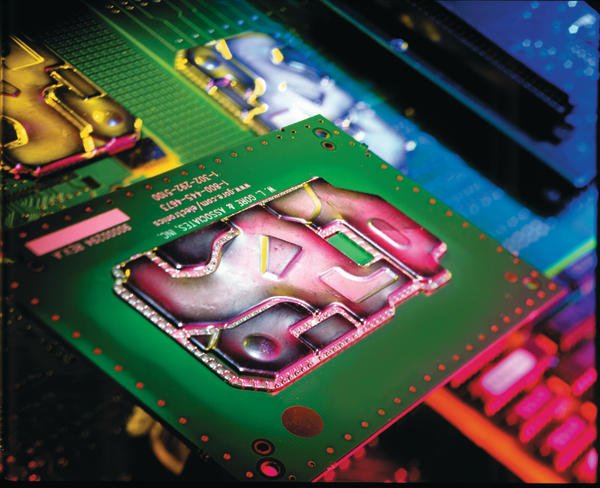

Target applications for this material include insulation for printed circuits, printed circuit board, disk drive, keyboard, inverters and adaptors, die-cut spacers, labels and overlays.Lexan EFR film can be easily fabricated using thermoforming, embossing, clean-edge die cutting, scoring and bending. The product is available globally in matte/polish and velvet/matte finishes and various gauges between 100 and 762 microns.

Share: