Anticipating the requirements for next-generation high-reliability electronics applications, Henkel Corporation announced the development of Loctite Eccobond UF 1173. The protective underfill material, which has been formulated with health and safety top-of-mind, does not contain any reportable Reach SVHCs (as per current, June 2018 Reach SVHC documentation), is not CMR classified and delivers outstanding performance under high operating temperature environments.

“The miniaturization trend is now firmly part of the automotive and aerospace sectors, particularly for advanced driver assistance system (ADAS) technologies such as cameras, radars and lidars; as well as aerospace, satellite and UAV applications,” says Global Market Segment Head for ADAS and Safety, Vinod Partha. “The use of fine-pitch array devices such as BGAs and CSPs within these systems has increased dramatically, making interconnect protection a critical component for long-term reliability and performance. Loctite Eccobond UF 1173 provides this essential protection in a formulation that can withstand the high operating temperatures induced by smaller, higher functioning devices within challenging operating conditions.”

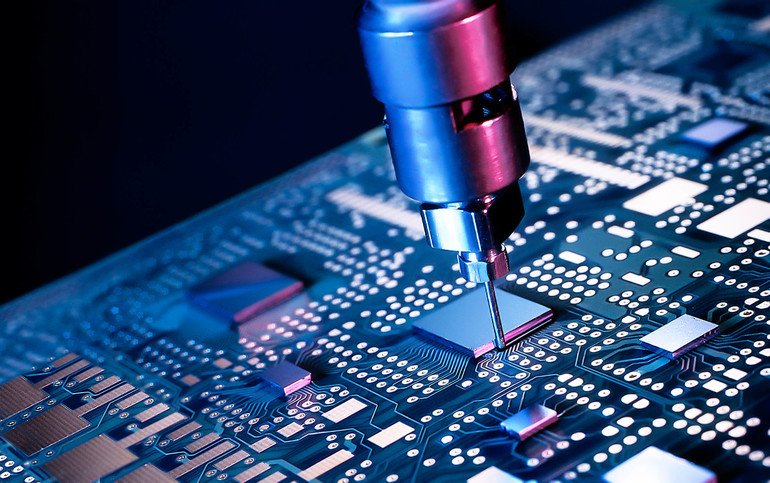

The company’s underfill system improves on older-generation materials, not only with its prioritization of health and safety, but also from a performance and processing perspective. It is a one-component underfill that can be jet or needle dispensed, flows fast in and around tight interspaces and cures quickly to form void-free interconnect protection from shock, drop and vibration. Importantly, it exhibits high glass transition (Tg) temperature capability of 155 °C and a low coefficient of thermal expansion (CTE) to ensure robust protection performance even under stressful conditions.

“Proper function of ADAS automotive systems and aerospace technologies is not a matter of convenience; reliable operation is integral to fail-safe performance,” explains Doug Katze, Global Market Segment Manager, Aerospace. “If a solder joint on a BGA cracks due to stress, failure of the component and the system’s function are the potential result. The underfill protects devices from stress-related failures, while complying with current health standards and offering the ability to cope with operating temperatures as high as 155 °C. This material is a boon for system reliability when harsh environments are the norm.”