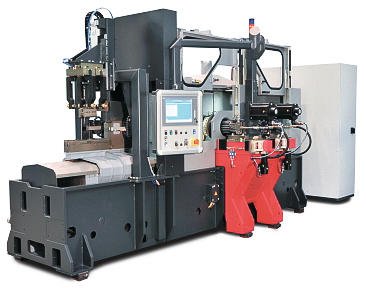

For extremely high product quality and productivity for treatment of silicon bricks the Arnold Group presents a high-end combination of a surface and chamfering machine, type 72/865. The worldwide accepted manufacturer of high-efficient processing machines, located in Weilburg/Germany, now disposes of a balanced production range in the grinding field with this high-end grinding machine which can serve the most different requests of customers. The innovative improvements and further developments of this high-end grinding machine are also integrated in the surface grinding machine 72/860 and chamfering machine 72/852. Furthermore they influence the combination machine, now available under 72/855. Whilst the new high-end grinding machine 72/865 fulfills the highest requirements in brick production, the combi-grinding machine 72/855 was designed for small- and middle-sized brick production capacities. Furthermore it completes the approved individual machines for surface and chamfer treatment. By the product improvements both individual machines were enormously appreciated and are now extremely suitable for high productivity due to the essentially shorter cycle times.

The high-efficient grinding machine with four parallely mounted grinding aggregates is suitable for grinding of lateral surfaces and for chamfering of squared silicon workpieces in the formats of 125 x 125 millimeters and 156 x 156 millimeters with an automatic format change. The extremely sturdy machine construction guarantees an excellent machine angularity and an extremely high absorption. The machine processing parts are casted with mineral composite. A new development, the cooling water guidance with a pressure of up to 25 bar, guarantees a balanced process cooling and hence reduces the water consumption by nearly one third. Current production and process data are stored, visualized and analyzed with the remote process analysis tool Arpat from the company and are the basis for the continuous optimization of production and process parameters.

This high-end grinding machine, immediately available, paves the way with the achieved values, to obtain the “Zero Error” strategies demanded by the manufacturer. A process capability of >1,67 Cpk at a tolerance of +/-0,05 millimeters can be achieved on a permanent basis.

With their extended grinding programme the company supports Photovoltaic manufacturers to realize individual production concepts and simultaneously complies with the industrial demands to reduce production costs significantly. The software tool, developed by the company, is a data base and controllable via Web-Browser and is an available option for all machines of the company.

Share: