Florida-based maker of adhesives, sealants, UV LED curing lights and dispensing systems Hernon Manufacturing has announced the introduction of two new acrylic adhesives: HASA 716 and UV React 795 Adhesives.

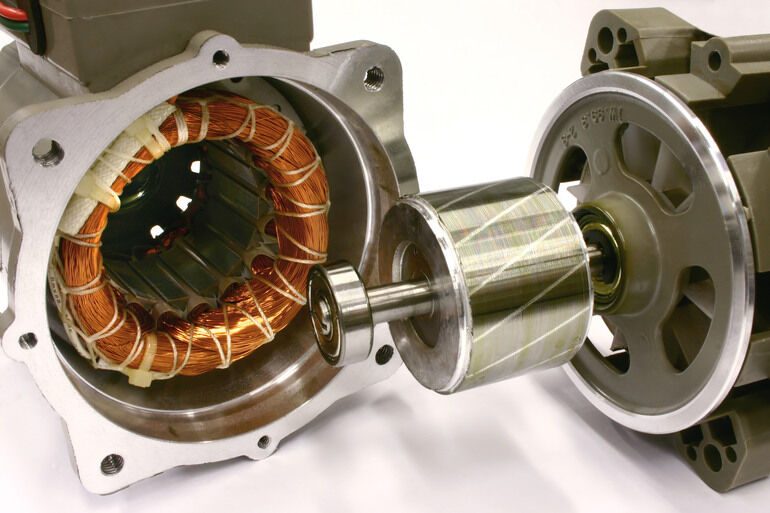

The company says that the former is an industrial-grade adhesive, a single-component structural anaerobic that excels in gluing together rigid parts in high temperatures. “It is designed to bond rigid assemblies permanently and ensure that the numerous magnets inside an electric motor do not shift or vibrate loose.

“UV React 795 is designed with permanent motor magnet bonding in mind and engineered to leverage high tensile strength and versatility to ensure that magnets stay where they should. It is impact and peeling-resistant, and when exposed to UV light, it cures to a permanent hard surface.”

The company says the two new products are able to “shrug off impacts, vibrations and heat, and as acrylic adhesives, serve as recommended substitutes for Loctite A533 and AA332”.

“Today, technological infrastructure like data junctions, under-sea data cables, battery packs and electric motors require top-grade bonding and sealants to ensure that sensitive internal components are safe in the air and water-tight enclosures, even in underwater applications. Marine vehicles also benefit from the extensive benefits rendered by high-grade modern adhesives. However, many industries and manufacturing as a whole, have improved by integrating advanced adhesives in their processes.

“The automotive industry, for example, is steadily gravitating towards electric motors. In an electric motor, the magnets’ prominent role is the generation of rotation, while a battery pack contains multiple batteries. These are both assembled and held in place by, you guessed it, adhesives. The battery pack provides the motor(s) with the juice to make rotation happen and produce both horsepower and torque.

“There are different types of industrial-grade adhesives intended to fill specific gaps in diverse manufacturing and production lines. Automotive battery packs for electric automobiles and electric motors call for optimally engineered adhesives for permanent bonding, ensuring that parts are glued and sealed to ward off water seepage and coolant leakages. If water seeps into a battery pack or an electric motor, corrosion will be the least of your worries. In the same breath, if the coolant leaks from the battery pack or the electric motor, heat will warp some components or burn others.