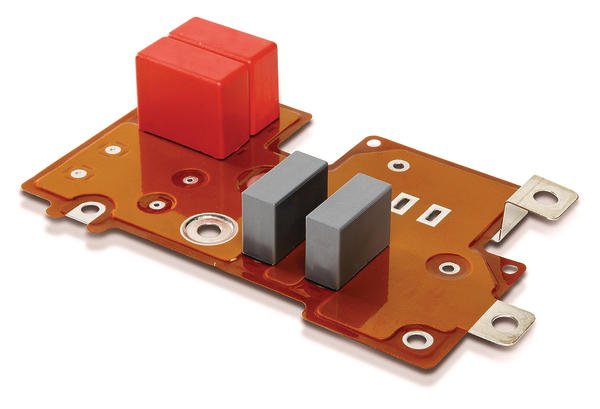

Rogers Corporation’s Power Distribution Systems Division has announced an innovative solution for emerging power electronics applications: RO-Linx PowerCircuit busbars. The PowerCircuit solution was developed to meet the growing power distribution demands in electric vehicle (EV) drives, hybrid electric vehicle (HEV) drives and related charging systems. Other significant applications include solar power inverters, uninterruptable power supplies (UPS) and industrial motor drives. The busbars fill the gap between printed circuit board (PCB) power distribution solutions and higher power laminated busbar systems. They combine the performance features of power PCBs and laminated busbars and are highly engineered solutions for multilayer power distribution delivering optimal thermal management. Unlike two dimensional (2D) power PCBs, PowerCircuit busbars can be made in three dimensions (3D) to reduce weight and footprint and to conform to specific engineering designs to maximize efficiency. In addition, PowerCircuits eliminate assembly steps at the end user reducing complexity and sources of error. Traditional power PCBs can handle up to 100 A current due to limited conductor layer thickness. Laminated busbars serve much higher power applications, generally at current levels from 500 A to more than 1000 A. The PowerCircuit busbars of the company fill the gap in designs for low to medium voltages and current levels. They are subsequently ideal for applications at current levels from 100 to 500 A, such as industrial variable frequency drives and HEV or EV motor drives. Furthermore the busbars can perfectly be combined with industrial mounting of functional components such as capacitors, sensors, and IGBTs. The new PowerCircuit busbars incorporate a closed mold design, using carefully selected materials engineered for high performance reliability in applications subject to conditions of high vibration and temperature cycling, such as in EV or HEV drives. 3D designs are well suited for medium to high volume assembly and most soldering processes. The busbars are also compatible with a number of different interconnect systems, including press fit, bolted-on, riveted, and common soldering methods assuring functional compatibility with today’s and tomorrows assembly technologies. They offer excellent thermal management properties, and achieve high power efficiencies while minimizing switching losses and reducing dangerous partial discharge and transients. They are ideal for use at lower to medium voltages, to about 690 V, and are compact and lightweight enough to support the latest power electronics designs in EVs and HEVs plus other mobile applications.

Share: