Dopag, a manufacturer of metering technology for adhesives, resins, silicones, sealing foams and lubricants, has announced the release of a new metering and mixing system called vectomix TC. The company, part of the Hilger & Kern Group, says the system has been developed for the reliable processing of thermally conductive materials, and has applications in electromobility and battery production.

Electromobility is currently one of the strongest growth industries. Electric cars, scooters and bikes are being manufactured in increasing numbers. Demand is also increasing in terms of mobile energy. There are more and more devices featuring rechargeable batteries, such as power tools, household appliances and medical products. Thermally conductive materials are processed during production. These materials typically contain a large amount of filler to enable them to fulfil their role, namely to conduct heat, the company explained. The vectomix TC metering and mixing system was developed especially for processing these types of filled, abrasive materials. The dispensing system is equipped with components made of wear-resistant materials. They are specially designed for the abrasive behavior of thermally conductive materials. Thus, they are protected from excessive wear and ensure consistently reliable processing with significantly reduced maintenance costs.

Modular structure enables high flexibility

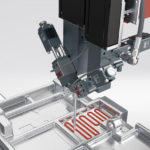

The system consists of two piston metering units which are available in different sizes and can be configured individually according to the application. For example, two piston metering units can be combined with different sizes. A hose package and a double valve for low handling weight in the case of robot applications can also be added. An individual piston metering unit can also be used for processing single-component materials. The modular structure enables a diverse range of applications as well as variable mixing ratios, shot sizes and discharge rates.

Both metering units have their own independent servo driver, which can be controlled separately. This enables high-precision control of the mixing ratio. The material can be discharged in shot or bead form. Multiple shots with one piston volume enable short cycle times.

Please click here to view an animation of the system.