“Frameless routing” is a new option to increase efficiency of depaneling with the IPTE depaneler, FlexRouter II. With this, depaneling of printed circuit boards is done without a frame, no PCB waste is left after milling. This technology increases the efficiency concerning ecological aspects by reducing not usable PCB waste. Therefore, a transport solution was developed for PCBs without a frame, to realize fast, stress free and precise depaneling with a milling spindle.

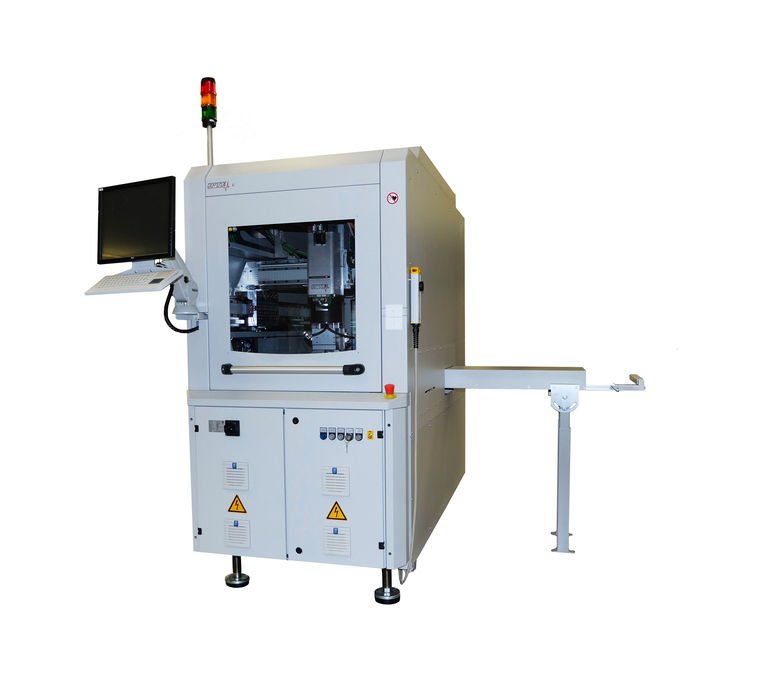

The FlexRouter II is aimed towards middle-sized to high volume production lots featuring a high variety of different PCB versions, these are the demanding high-mix depaneling tasks based on short machine set-up procedures. Despite the very small footprint (machine width is only 500 mm), boards with sizes of up to 330 mm x 400 mm can be processed without difficulties. Four of the seven machine axes in total are integrated as extremely precise linear drives of latest technology. In the FlexRouter II, the PCB panel will be fed in, securely clamped and its position precisely identified and adjusted by use of a precise measurement system. Since a freely programmable servo-gripper is used for clamping during the cutting operations, a panel-specific gripper is usually not needed, and there are no additional gripper-tooling costs. The gripper mechanism features a Cartesian 3-axes system assembled on a rotating axis. The milling spindle under the panel is also positioned by a Cartesian 3-axes system and can be equipped with different spindle types. With these functions, applications can be realized without intricacy. As the gripper fingers are exchanged automatically, the change-over from one product to another is remarkably fast and easy.

After the milling spindle has cut a single PCB from the panel, the board is set aside and clamped by the gripper. For this step, a wide variety of different PCB stacking options are obtainable according to customer requirements in order to receive an optimum process flow, such as dual and single tape conveyor feeder, tray module to a size of maximal 600 x 400 mm, work-piece holder, linear shuttle or rotating table for the subsequent and individual customer procedures. Also available as an option is the accurate measuring of the singulated PCB by AOI technology.

The generation of new routing programs will be aided and made faster through the use of a camera-based system or the integrated DXF-converting software, which supports the fast and uncomplicated CAD data acquisition. The machine user-interface is designed for the intuitive and easy execution of all necessary functions of the FlexRouter II. There are many special standard features implemented in this new solution, such as a provision for the usage of various sections of the milling head in order to reduce the costs, the automated exchange of milling tools and a detection function for their possible break down.

The main focus in developing and enhancing the company’s depanelers is to fit the requirements of the market’s and customers’ needs. By doing so, the performance and the quality are on a very high level. With the model SpeedRouter, launched 1998, IPTE has made flexible machine configurations, which are capable of in-line integration, allowing a reliable and low stress routing process of large panels containing multiple boards. According to the PCB layout, the routing can be done with milling and sawing actions, or by a combination of both cutting methods. The company’s large portfolio of options and add-ons for the system periphery efficiently support the integration in already existing lines. Their depaneling machines are suited for specific requirements in applications where tight tolerances are of essence.

The company can provide the appropriate solution for practically every depaneling application from its full-sized set of different router systems, depending on product-mix, the manufacturing quantity and the degree of automation needed on the shop floor. Their system portfolio now consists of the EasyRouter, TopRouter, FlexRouter II and SpeedRouter. All machines are energy-efficient; they have a high availability and very small footprint. Furthermore, the machines are Industry 4.0 ready. Optionally integrated AOI solutions, including a 100 % control of the process, complete the portfolio.

IPTE’s experience results in an installed base for a large variety of applications, which is also apparent in the design of the dust-suction system for the minimization of milling particles and the air ionization. High-level hardware and software solutions have been optimized and designed for the individual product and the production process for a high throughput and availability. The following functions are available to be installed in the company’s depanelling machines: process statistic and monitoring pages, direct import of customer DXF-files for the cutting program generation and easy integration to work on a wide variety of MES systems.