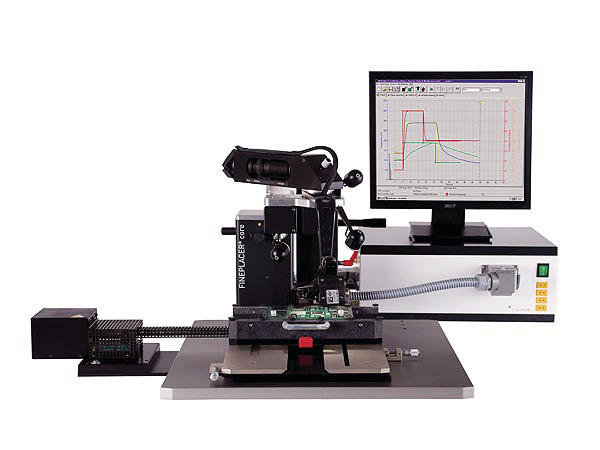

The effective rework system, the Fineplacer core provides an out of the box solution and is based on Finetech’s proven hot air technology, that has been designed to meet the requirements of professional rework applications. This compact rework station allows integration of the complete rework cycle: component removal, site cleaning, re-balling (array), paste printing (component, PCB), paste dipping, fluxing and soldering, all with an efficient design and without diminishing functionality. The Fineplacer core features a placement accuracy better than 25 µm, advanced thermal management with integrated hot air top and bottom heating, the patented vision alignment system, automated processes, force measurement and nitrogen support as standards. The tool offers professional rework capabilities for a wide spectrum of SMD components commonly found in consumer electronic environments. The application area ranges from chip sizes of 0.25 up to 50 mm on board sizes up to 400 x 300 mm. The thermal management provides coordinated control of top and bottom heating as well as all process-related parameters: temperature, flow, time and process environment. Automated processes with force measurement allow user-independent operation after alignment and guarantees highly reproducible process results.

SMT/Hybrid/Packaging

Booth 6-406

Share: