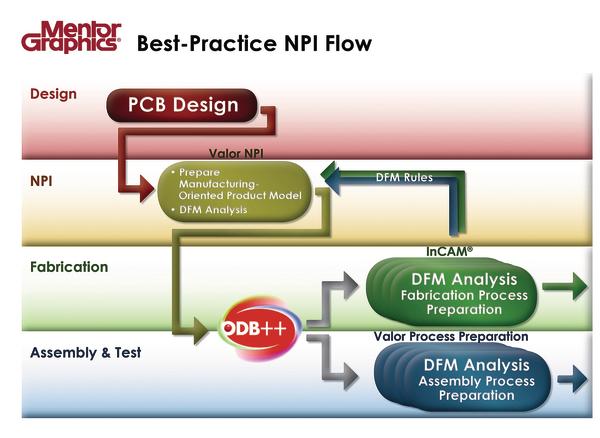

Mentor Graphics Corporation announced during the Apex show its unique new product introduction (NPI) solution that seamlessly links printed circuit board (PCB) design and manufacturing operations to deliver the industry’s first integrated, automated flow for the design, fabrication, and assembly of PCBs. The Mentor Graphics Valor NPI software product helps the design- and product-level NPI engineer prepare and validate product models according to the manufacturer’s rule-set in the engineer’s native design tool. This ensures a perfect design for production, without requiring specialist manufacturing knowledge or expertise. This then enables the process-level NPI engineer to evaluate and create process toolkits with no manual data entry, so the manufacturer will have a “right-the-first-time” design to eliminate production errors. As the market share leader in PCB computer-aided manufacturing, the company closes the gap between the designer and manufacturer. Now, the manufacturer can create and adjust the rules to meet manufacturing requirements that the designer can follow for a truly bi-directional, consistent, one-rule flow. Mentor Graphics lean NPI solution benefits NPI product and process engineers by reducing design re-spins, improving overall product quality, and shortening product delivery schedules.

The lean NPI flow solution provides a true PCB design-through- manufacturing solution by first preparing and verifying the final PCB product model definition, then delivering that product model through the manufacturing process definition, factory floor tooling, and documentation creation stages. The lean NPI flow leverages the ODB++ v8 open standard for intelligent design-to-manufacturing data transfer. The lean NPI flow is available and is comprised of the Mentor Xpedition platform, the Valor NPI and Valor Process Preparation products, and the Valor Parts Library, to create the industry’s most complete, highest-performance, and best practice lean NPI flow. The lean NPI flow also optimally supports Frontline PCB fabrication tools and several ODB++-compatible third-party tools.

SMT Hybrid Packaging

Booth 7-208

Share: